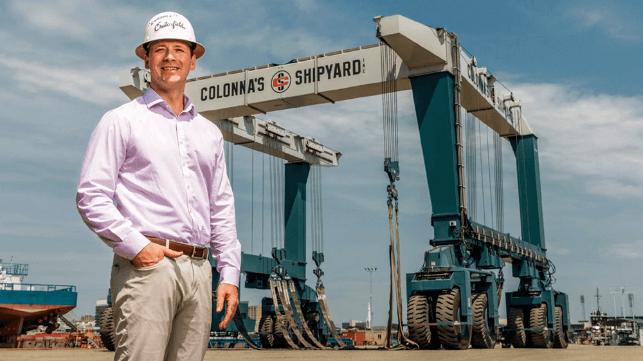

Interview: Randall Crutchfield, Chairman & CEO of Colonna's Shipyard

(Article originally published in May/June 2025 edition.)

The fifth generation to run the family business, Randall Crutchfield is both humbled and challenged by his new role.

Welcome, Randall, and congratulations on 150 years of achievement! Let's start with a brief history of the company, in your own words, and some of the milestones along the way.

Yes, sure thing. So my great-great-grandfather, Charles J. Colonna, was a ship's carpenter who settled in Norfolk, working for another gentleman who owned a shipyard, which was just a marine railway. That was the technology back then.

He decided to set out on his own but needed some money to do so. Meanwhile, his older brother, Benjamin A. Colonna, who went to Virginia Military Institute and was the only Colonna of that generation to be able to go to school, had made an agreement with their father that, because he had the opportunity to go to college, he needed to look out for his other siblings. So part of living up to that deal was a $2,000 loan to his brother Charles to build a marine railway here in Norfolk.

And that's how the shipyard started.

A lesser known piece of that history was that the $2,000 was actually not enough to get the shipyard off the ground, and Charles had to borrow another $2,000 a couple of years later. But it all worked out.

In 1891, the Colonnas put in a second and third marine railway. Amazingly, the #3 Marine Railway is still in operation today and is booked solid. So it's very cool to be able to walk folks around and show them that piece of equipment that's been around for 135 years.

What's a marine railway?

It's a way of hoisting ships out of the water so they can be worked on. They were originally powered by horses. Picture a king post in the ground with a chain attached to it and two horses pulling the chain around the post, hauling the ship up. That was our first marine railway, and it could lift 40 tons.

Fast forward to 1920, when the #4 Marine Railway was installed. It had a capacity of 4,000 tons, which we believe was the largest in the world at the time. It was in operation for nearly 100 years and finally retired in 2014.

Amazing! What came next?

We trace our history through different eras, and the first hiccup came during World War I.

We were having conversations with the Department of Defense, which needed more capacity. So we installed the infrastructure to be able to meet that need. But we were a little bit late getting there because the war wound down at the same time we were building out this infrastructure, and we ended up in pretty tight times.

Then came the Great Depression and things were really tight. But we always stayed true to our legacy customers – the fishing boats, the transportation companies locally, barges, dredges and Navy work where and when we could. World War II came and we were busy again, and it was after the war that my granddad took over.

He was a big idea guy, and he took this sort of laid-back shipyard and hired the right managerial staff to grow it successfully. And that led to a lot of expansion.

But there was one last wrinkle. And look, you don't stay around a long time without some hardship. We landed a really nice contract with the Coast Guard in the late '80s. We had just bought a 16,000-ton drydock, and the contract was going to be the next big thing for Colonna. But the government terminated the contract, and we wound up filing Chapter 11 and doing a workout.

But the really cool thing about it is there are still people around who remember those really lean times and can tell stories of how tight things were and the sacrifices people had to make to stay at Colonna's, including foregoing portions of their paycheck for some periods of time.

But they were committed to the vision of the leadership and ownership here, and it wasn't a hard decision for them because they knew we were going to keep our word. That was a really poignant message for me – that folks had faith we were going to do the right thing, even if it was hard. And we did.

A great lesson to learn at any age.

Yes, it was.

So we dug out of that under the leadership of my granddad and a gentleman named Tom Godfrey. We started being really successful in our legacy ship repair work with the marine railways and drydocks, and we became a lot smarter about both the commercial and government work we were doing. That allowed us to start investing heavily in our infrastructure and our corporate structure.

We started Steel America, which is our heavy fabrication machining business. We started doing what we call Down River services at government installations and larger shipyards in the port. And we also started a temporary staffing company called Trade Team, all around the year 2000 timeframe.

So with the shipyard doing well, the legacy ship repair business doing well, and then these other handful of businesses being largely successful from the outset, it allowed us to really expand in granddad's later years.

He bought back several parcels, probably 40 or 50 acres of land that we had gotten rid of over that previous 100 years. And now we're able to incorporate that into what has become a 120-acre waterfront facility.

We added more than 100,000 square feet of industrial shop space with heavy cranes inside to do structural fabrication and machining. We bought a 1,000-ton-capacity marine Travelift in 2009, the largest ever built at the time, and added a third drydock in 2016.

These investments were all successes because we took a long-term approach. We weren't looking for a payback in three years or five years or anything like that. We just felt it was the right thing to do even if it was the hard thing to do.

Well, it's worked for 150 years.

It has. For me, putting things in the context of 150 years and connecting that to the business approach that, if we do the right thing, it's going to pay off long-term, sums up how my granddad and his father and grandfather really thought about the place. They never thought about it as a way to make lots of money for themselves. They always thought about it from the perspective of a caretaker – taking care of the facility and taking care of all the families that have worked here. And that's my perspective too.

Tell us about your management team. Who are the key members?

Yes, so we'll start with Jordan Webb. He's my #2 – President and General Manager. Jordan came to us in 2007, fresh out of Virginia Tech, and he just worked his way up through deck plate repair management – the "school of hard knocks" here at Colonna's.

Chris Hartwig did the same thing. He manages Steel America. He came around 2007 as well, straight out of college. The rest of the leadership team includes Rebecca Wieters, our CFO, who does a great job, and Chris Bates, who runs a company in Owensboro, Kentucky called Accurity Industrial Contractors.

Accurity's an interesting story. We were looking to diversify and wanted companies that matched our culture and also understood the concepts of project management and craftmanship. We met Chris about four years ago and acquired his company two years later. They work in the industrial power market. They're process pipe experts, so think about combined cycle power plants, coal-fired power plants, gas power plants.

It's no different than what we do in the shipyard – project management work that relies on blue collar, skilled tradespeople We've been able to share work back and forth. We've gotten them involved in some Department of Defense work, and they've helped us with some pipefitting on ship repair contracts and ship construction contracts. We're starting to realize certain synergies, which is really positive.

How many employees are there overall?

We typically carry 700 to 800 employees. Accurity in Kentucky generally runs about 100. Our West Coast facility in San Diego, called Colonna's Shipyard West, is only about 30 people, and everything else is here on our Norfolk campus. It's all one big campus – Colonna's Shipyard, Down River, Steel America, Weld America and Norfolk Barge.

You have all of these different divisions, and yet the name of the complany is simply Colonna's Shipyard. Why is that?

Yes, my granddad was firm that that's always going to be the name. It's just part of who we are – being steady and holding true to the legacy. And that's why it's always going to be the name.

Is there a good workforce in your area?

We have some of the greatest people in the U.S. working right here in Norfolk. Unfortunately, too many people have been swayed by the notion that blue collar work isn't for Americans. So we've got some convincing to do to really get folks in the younger age groups to realize that these are great-paying jobs and you don't need a college degree to get them.

What's your biggest concern right now?

I think for the country to be viable for the next generation, the big concern for folks in my position is making sure people realize that shipbuilding and ship repair are necessary not only for our national defense but for how we operate commercially.

So we've got some decisions to make, and they're going to be hard decisions. Do we want to continue to outsource everything we can or do we want to have a domestic manufacturing capability? And if we make a bad decision there, that drives right to the heart of what Colonna's has always been about, which is a blue collar, project management organization. And if as a country we decide that's not important to us, I have to go find something else to do for a living, right? And so do the 800 people that we have employed here.

Heavy stuff! Any final words for our readers?

Yes, I love what I do, and it's humbling for me to have the opportunity to be able to do this and do it for my family and for all the families that have contributed to this place. Just think about the thousands and thousands of people who chose to work here. You can go do anything else in the world.

So I feel a sense of gratitude and also an obligation to those people to do the right thing, even if it's hard, to make the best decisions for all of us as much as possible. And I believe that over time, if you have that intention and that guiding principle, it's going to aggregate to making a lot of good decisions.

Are we going to make bad decisions? Yes, but can we make them fast and then fix them fast? That's really key for me. And that's how I look at things.

Tony Munoz is founder, publisher and editor-in-chief of The Maritime Executive.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.