Opinion: Grey Water Related Non-Conformities Need to be Addressed

Manufacturers are there to innovate, to compete, to think outside-the-box and to test boundaries. However, there is a line, drawn up by the IMO, in the form of Conventions and Guidelines that defines what is acceptable and what is not.

One would hope that those who crossed the line would be reined in. But instead, there is a situation where they are rewarded with certificates and acceptance, and this needs to be highlighted so that the issues can be addressed.

The joint paper below explores a non-conformity with marine sewage rules. It follows previous joint-papers on chlorination disinfection without de-chlorination, no-sludge and recirculation-via-influent. These non-conformities are widening the gap between rules and realities.

Grey Water to the Final Stage of Sewage Treatment Plants - A Non-Conformity Awarded with ‘Green’ Notations

Co-authored by:

Dr. Wei Chen, Future Program Development Manager, Wartsila Water Systems Ltd, UK

Mark Beavis IEng IMarEng FIMarEST, Managing Director, ACO Marine s.r.o., Czech Republic, ACO Marine Systems GmbH, Germany

Dr. Daniel Todt, Project Manager R&D, Ecomotive AS, Norway

Felix von Bredow, CEO, HAMANN AG, Germany

Dr. Elmar Dorgeloh, Manager Director, Development and Assessment Institute in Waste Water Technology at RWTH-Aachen University (PIA), Germany

Endorsed by:

Ronni Palmqvist, Director and Owner, Dancompliance ApS, Denmark

Helge Østby, Senior Technical Advisor, Jets Vacuum AS, Norway

Benny Carlson, Chairman and owner, Marinfloc, Sweden

Antony Chan, Engineering Manager, Victor Marine Ltd., UK

Tobias Kaulfuss, Manager - Marine Sewage Treatment, RWO - Veolia Water Technologies Deutschland GmbH, Germany

Holger Hamann, Managing Director, Holger Hamann Consulting GmbH, Germany

Dr. Gerhard Schories, Head of Institute, ttz Bremerhaven, Germany

Markus Joswig, Head of Marine Department, Testing Institute for Wastewater Technology GmbH (PIA GmbH), Germany

Niclas Karlsson, Managing Director, Clean Ship Scandinavia AB, Sweden

In the marine industry, grey water is defined as wastewater from accommodation showers, wash basins, galleys, dish washers, and laundries. To discharge such wastewater untreated is unimaginable in many parts of the world, whether it comes from a single laundrette in a coastal village, or from a lone shoreside restaurant. Ships, however, can discharge untreated grey water anywhere. Concerns have been raised with the IMO over the years [1], but to no avail.

Classification societies have been encouraging grey water treatment by offering green notations for those that do. It is an attraction for ship owners looking to promote greener fleets. But, in the absence of rules, what does grey water treatment entail? And how to prove it? Few seem to care.

To comply with MARPOL Annex IV and its Guidelines, grey water should be subject to the same treatment process as sewage. Many manufacturers follow the rules by increasing the size and capacity of the sewage treatment plants to accommodate grey water treatment. However, in a few cases, certification has been awarded to sewage treatment plants having the grey water connected to the final sewage disinfection stage (Figure 1), even though pollutants in the grey water would render the disinfection stage ineffective, causing poor performance status. But there are commercial incentives: the grey water can be ‘treated’ without increasing the size of the equipment or the treatment capacity, and furthermore, a dedicated grey water collection system may be waived.

Figure 1. Wrongly approved grey water connection

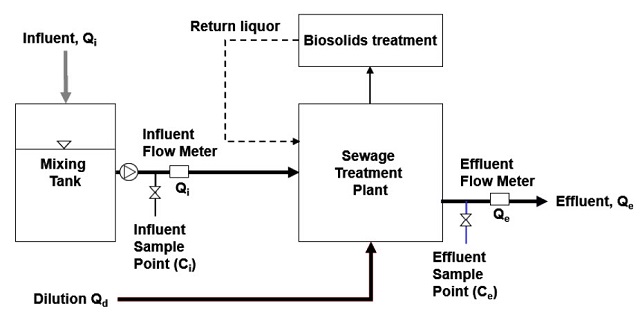

MEPC.227(64) introduced a Dilution Compensation Factor, Qi/Qe (Figure 2) with the intention to tighten the discharge limits of dilution machines. When Qd is introduced downstream of the influent sample point (Ci) and the influent flow meter (Qi), the Qi/Qe factor is < 1. However, when its certificate states Qi/Qe = 1, and grey water is being introduced to the final sewage disinfection stage, it is not only a problem, it is a non-conformity.

Figure 2. System diagram in MEPC.227(64).

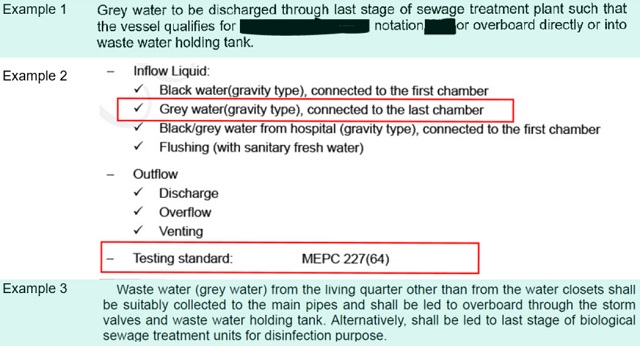

Such low-cost, small-footprint ‘solutions’ have been in demand, and have even been written into new build ‘green ship’ specifications (Figure 3). Manufacturers who have followed the Guidelines cannot even bid, let alone win.

Figure 3. Examples of shipyard specifications demanding non-conformities that had been certified.

This non-conformity has been raised in the public domain for years [2]. In March 2019, MarED, the co-ordination group for the Notified Bodies assigned by the EU Member States to carry out conformity assessment procedures for marine equipment placed on board ships flying one of their flags, published an Approved Recommendation [3]. It states, when the certified Qi/Qe=1, there shall be no connection available to lead grey water in the final stage of the sewage treatment plant. In accordance with Article 23 of Directive 2014/90/EU, multiple relevant manufacturers should have been requested to take appropriate corrective measures ‘without delay.’

But why was this non-conformity approved and rewarded in the first place? How can we stop such grey water related non-conformities from happening again? Despite this positive signal by MarED, the root cause of this non-conformity remains unknown.

Is grey water to blame? Grey water accounts for 40-50 percent of the total organic matter from residential houses [5], and an even greater portion from ships [6]. The situation being as it is means that grey water from ships not only pollutes coastal waters, causes non-conformities, but also erodes the green notations. While no one wants to dampen the enthusiasm to go beyond the rules and be ready for the future, there should be awareness of such certified pitfalls.

Let’s hope to hear some feedback as a result of the MarED recommendation. Let’s hope to see corrective actions from beyond the EU. Let’s hope the root causes are understood and visible. Let’s hope such insights would benefit the on-going efforts to make MARPOL Annex IV effective. Let’s hope.

that matters most

Get the latest maritime news delivered to your inbox daily.

References

[1] MEPC63/2/18, MEPC 64/7/7, 2012; DE 57/11/14, 2013; MEPC 68/INF.37, 2015; MEPC 72/16/6, MEPC 72/INF.21, MEPC 73/INF.28, 2018.

[2] Monitoring required for compliance with standards, by W. Chen, Ship & Offshore, GreenTech, 2014.

[3] MarED-18-715, POL-010, Rev 5. https://www.mared.org/public/approvedRecommendation/

[4] MEPC 74/14

[5] Load and distribution of organic matter and nutrients in a separated household wastewater stream, by Todt D., Heistad A., Jenssen P.D. Environmental Technology. Vol. 36. Nr. 12, 1584-1593, 2015.

[6] Cruise ship wastewater – a presentation to the Science Advisory Panel, by Meyer Werft, Alaska, 2011

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.