Navigating a Multi-Fuel Future: Innovation at the Heart of the Transition

The global maritime industry is advancing toward its decarbonization goals, and one message is becoming increasingly clear: there will be no single solution or silver bullet. While future fuels will be a key driver, the sector is preparing for a multi-fuel future, where a variety of low- and zero-carbon options will coexist, each suited to different vessel types, trading patterns, and regulatory environments. Whichever fuel ship owners opt for, they need to be safe, fit for purpose and underpinned by reliable fuel supply systems.

With over 50 years of experience in developing next-generation fuel supply systems, Auramarine is playing a critical role in supporting this transition by building technologies that are fuel-agnostic and capable of adapting to fast-changing requirements. However, in a landscape still marked by uncertainties, ranging from fuel pricing to flexibility and global availability, ensuring confidence and risk mitigation in day-to-day fuel handling remains a pressing priority.

Methanol and ammonia: Growing roles and challenges

Looking toward 2050, many analysts expect a significant share of marine fuel demand to be met by methanol and ammonia. For instance, the International Energy Agency estimates ammonia could make up 44% of marine fuel use, while Lloyd’s Register forecasts 20%.

Both fuels offer promising Greenhouse Gas (GHG) emissions reductions but price, availability, a robust regulatory framework to ensure safety and the development of the right bunkering and supply infrastructure will be key factors in driving their widespread uptake.

Ammonia, for example, carries more complex safety requirements. From gas and leak detection to crew training, ammonia’s adoption will rely on robust safeguards and regulatory clarity. Safety measures include gas and leak detection, ammonia capture, reliquefying and ammonia release mitigation (ARMS) functions.

Adopting alternative fuels, therefore, isn’t a straightforward ‘plug-and-play’ exercise; it requires holistic consideration of the vessel design, supply chain readiness, safety measures, crew training and more.

Innovation in focus: Auramarine Water Content Analyser

At Auramarine, our focus has been on enabling the industry to use alternative fuels safely, efficiently, and reliably at sea through robust research, development, experience, and partnerships. As methanol gains traction as a marine fuel, one critical challenge is emerging: water contamination. The presence of water in methanol can increase fuel consumption, an issue exacerbated by the limited availability and relatively high cost of methanol. Ensuring the quality of methanol is therefore essential, not only for operational efficiency but also for managing fuel costs effectively.

In response to this need, we have developed the Auramarine Water Content Analyser (AM Water Content Analyser). Launched at Nor-Shipping 2025, the technology is designed to measure and report the concentration of water in methanol, helping ship operators proactively monitor fuel quality. By doing so, they can maintain optimal engine performance and achieve cost efficiencies through consistent fuel quality.

Put into the context of the energy transition, consider a ro/ro vessel using 27,000 tonnes of green methanol annually. With green methanol priced around €1,196 per tonne, a 5% water contamination could lead to losses exceeding €1.6 million over the course of a year. Detecting and responding to such issues early can prevent both cost overruns and operational delays.

Put into the context of the energy transition, consider a ro/ro vessel using 27,000 tonnes of green methanol annually. With green methanol priced around €1,196 per tonne, a 5% water contamination could lead to losses exceeding €1.6 million over the course of a year. Detecting and responding to such issues early can prevent both cost overruns and operational delays.

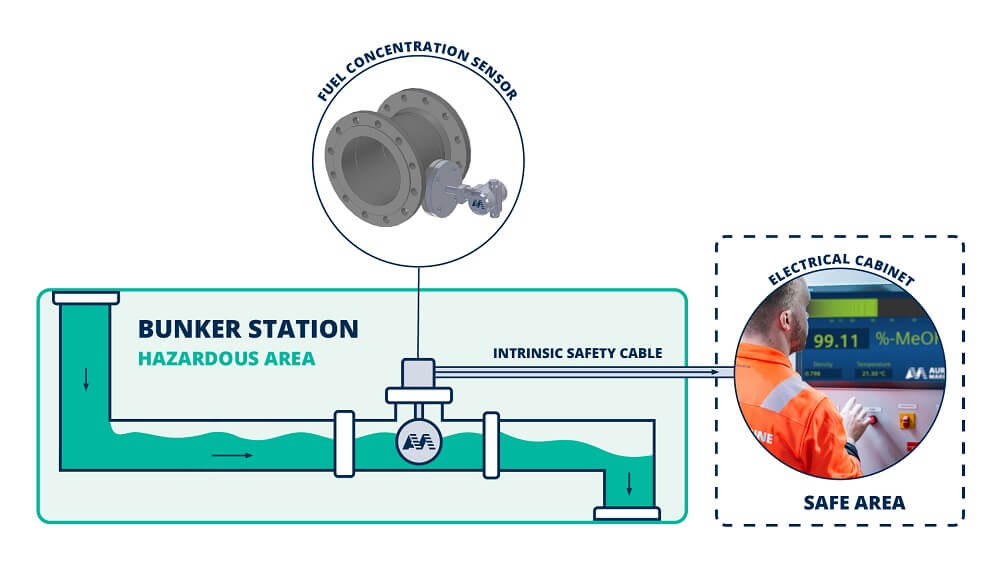

Auramarine’s technology is installed directly to the methanol process piping and uses a sensor to provide continuous data on water concentration. This allows operators to verify the quality of their fuel before and during use, which is especially valuable in remote or tight-schedule operations.

The AM Water Content Analyser is a strong example of the incremental, highly practical technology that will support the broader adoption of cleaner fuels. It also illustrates the importance of closing smaller, operational gaps that could otherwise slow the pace of fuel transition.

Looking ahead: Integration, collaboration, and confidence

As vessels built today will likely still be operating in 2050, the imperative for flexibility and future-proofing operations is clear. Fuel supply systems must be adaptable to different fuel types, offer safety by design, and be backed by comprehensive research, training and lifecycle support to ensure their ongoing integrity and operational efficiency

Operators must be able to rely on consistent quality and performance, both from the fuels and the systems that support them. Whether it’s real-time quality monitoring for methanol or integrated safety systems for ammonia, the marine sector will depend on technologies that address specific, real-world operational challenges.

The broader takeaway is that while the path to decarbonization may be complex, progress is being made step by step. By focusing not only on the fuels themselves, but on the supporting technologies that enable their safe and efficient use, the industry is laying the groundwork for a resilient, multi-fuel future.

To learn more about the Auramarine Water Content Analyser, visit: https://www.auramarine.com/am-water-content-analyser/

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.