Cutting Chain Failure Forces Golden Ray Salvors to Shift Efforts

Shortly after restarting operations on the third cut through the hull of the wrecked ro/ro Golden Ray, salvors have been forced to stop work again and shift to the next section due to another broken chain link.

On Friday, the 31st day of work on the third cut, a link in the cutting chain failed again - the latest in a series of link and connecting link breakages during operations. This took the chain out of the cut groove for Section Seven (the third hull section in the cut sequence, centered on the engine room). Divers will have to survey the hull and the cut, then install a system to position the chain back in the groove. According to the response team's engineers, the wreck remains stable.

VB 10000 repositions as it prepares to shift to the cut for Section Two (St. Simons Sound Incident Response)

While the dive work proceeds, the heavy lift barge VB 10000 will shift over to begin cutting for Section Two (the second section aft from the bow). The pre-cutting work for the next sections in the sequence has been intensified, with salvors using torches to cut strips of hull plating away along the expected groove.

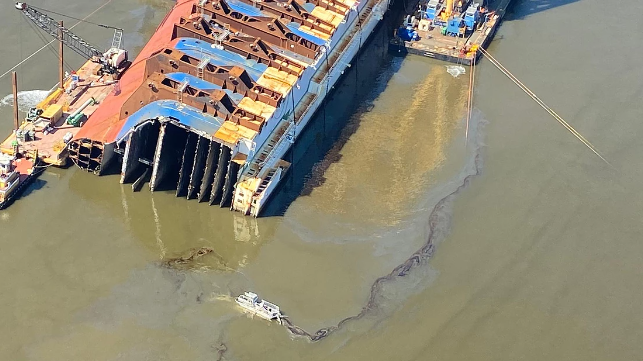

The response team is still finding and recovering oil sheens and debris from the water around the wreck site, as expected in the salvage plan. Petroleum leakage from the hull has recently increased: the third chain cut passes through the ship's engine room and the fuel lines that lead to it. More than a dozen skimmers and pollution response boats were deployed late last week to clean up slicks inside and outside of the environmental protection barrier surrounding the wreck site, according to the Brunswick News. Survey teams are also deployed on the shoreline to find and remove any debris or globules of fuel oil.

The salvage team reports that a majority of the oil has been contained within the barrier, which encircles the entire site with containment boom and steel netting. The expectation prior to the commencement of work was that some pollution would occur during cutting, as salvors cannot safely access and remove all of the potential reservoirs of fuel within the hull. Spokesman Michael Himes told the Brunswick News that the containment barrier was working as designed, minimizing the impact of an all-but-inevitable release of fuel oil during operations.

that matters most

Get the latest maritime news delivered to your inbox daily.

Fuel oil spill cleanup inside of the environmental protection barrier, February 25 (St. Simons Sound Incident Response)