Underway Hull Cleaning Boosts Efficiency Without Schedule Disruption

Regular hull cleaning is necessary to reduce carbon emissions and comply with regulatory requirements. However, operational challenges sometimes interfere with this process. Diver-operated services are costly and in-water hull cleaning is not available in all seaports. Fully autonomous cleaning under way would resolve all these issues. Israeli startup NakAI Robotics has developed a robotic system that does exactly that.

NakAI's hull cleaning and inspection robot is designed to remove early-stage biofouling from the hull while the ship is in transit. Even light accumulations of fouling can raise fuel consumption by 10 percent, enough to affect a vessel's CII numbers and the owner's bottom line.

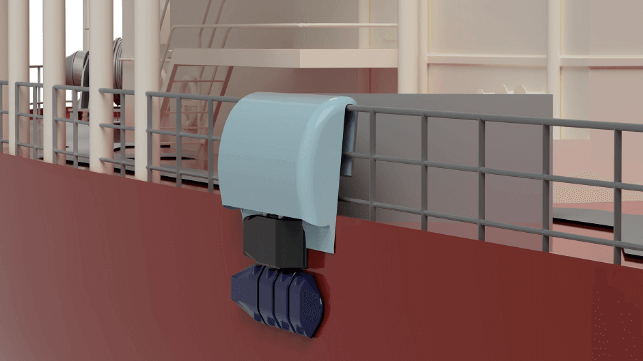

NakAI's solution offers shipowners and operators a practical way to operate with a continuously clean hull. Its robot self-deploys from the side of the ship to clean the bottom, without cabling and with no additional effort from the crew. Most importantly, it is designed to operate while under way, using hydrodynamic forces to hold itself against the hull - just like a remora fish on a whale. It gently cleans all hull surfaces except for the bulbous bow and the area near the propeller, where turbulent flow makes it difficult to operate. Everywhere it goes, the robot's UV- and brush-based cleaning mechanism clears off slime, leaving soft bottom coatings unharmed.

"Nobody currently cleans their hull every week or every month, but we can actually provide that," says NakAI CEO Aviv Melman. "Think of it like a Roomba® for ships."

Since NakAI's system cleans while at sea, there is no disruption to in-port operations or vessel scheduling. The novel method also resolves regulatory and compliance hurdles, since there are no restrictions on hull cleaning on the high seas, nor any of the safety precautions needed for diver cleaning teams.

NakAI is working quickly towards a commercial ready solution. The company cleaned its first cargo vessel in Israel in August 2021, and it is receiving considerable interest from shipowners in the Mediterranean and beyond. The objective is to have an off-the-shelf system ready to go to market in the second half of 2023.

"We are significantly less expensive than existing solutions while providing immense potential savings. NakAI’s robot is the only solution to address the invisible slime layers that are adhere to the hull every minute," says Melman. "Everybody appreciates the fact that we are providing continuous cleaning, preserving the antifouling paint, and maintaining optimal hydrodynamic performance over time."

As an important secondary benefit, NakAI's future products will be fitted with class-approved inspection sensors. The robot will scan the hull as it cleans, giving the shipowner early warning of any maintenance issues that need attention. "Since NakAI is modular, flexible, and redundant, we can add these sensors and we've already started the process to get classification approval," says Melman.

The ideal early-stage customers for the product are owners of bulkers, tankers, and other cargo vessels. Interest is strong enough that NakAI already has enough offers in the pipeline for unpaid proof of concept trials, and talks are under way for the first paid trials, Melman says. The firm is ready to scale up quickly with in-house manufacturing capability for the majority of the robot's components.

The CII regulation is a clear driver for interest in hull cleaning, but Melman sees an even bigger regulatory factor on the horizon – hull fouling. "We are waiting eagerly for worldwide biofouling regulations." he says. "We think that this is where the market will go and we intend to be ready for it."

This message is sponsored by NakAI Robotics. For more information, please visit https://www.nakairobotics.com/

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.