In It for the Long Haul

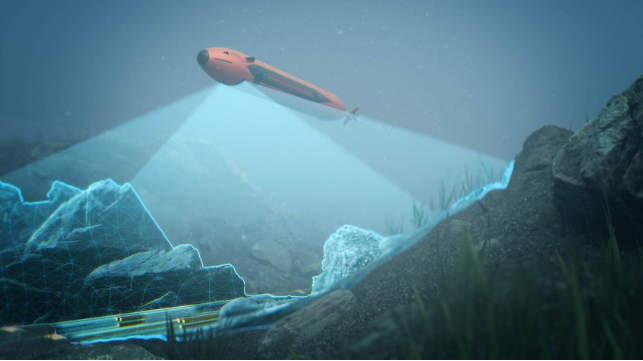

Until recently, Autonomous Underwater Vehicle (AUV) operations have been viewed as a logical next step from those carried out with Remotely Operated Vehicles (ROVs). Launched from a ship, AUVs can autonomously carry out complex underwater survey tasks leaving the surface vessel to monitor its progress, potentially managing other AUVs or undertaking additional survey duties at the same time.

However, reliance on a ‘mother ship’ incurs significant cost, especially if it is purely there for monitoring and charging. But to take the next step – making the AUV truly independent – means dramatically increasing its range so that it can realistically carry out operations far from any support infrastructure. This includes starting missions from shore.

That’s exactly what Kongsberg Maritime have done with the launch of the latest addition to its HUGIN range of underwater survey platforms. Rated to a depth of 6,000m and designed to facilitate unsupervised, long-range, multi-role operations, the new HUGIN Endurance lives up to its name by offering a previously unthinkable mission time of up to 15 days. This means that it can autonomously carry out complete operations spanning approximately 1,200 nautical miles – equivalent to the sailing distance between New York City and the mainland of Cuba, or between Venice and Alexandria in Egypt. Set this against the average 12-to-36-hour endurance hitherto achievable by most AUVs, and it’s easy to appreciate how massive is the difference made by recent developments in pressure-tolerant lithium-ion battery technology. s

In shore-to-shore survey applications, the AUV’s ability to operate autonomously for such a lengthy duration could, in many cases, dispense altogether with the need for a dedicated support vessel. The knock-on effects of this would be a considerable reduction in operational carbon footprint coupled with a sizeable increase in the potential weather window, plus a welcome safety boost as crew could be redeployed for shore-based duties.

Even when a support vessel is required there are still significant advantages, as Richard Mills, Vice President Marine Robotics Sales at Kongsberg Maritime, explains. “There are practical and financial benefits for a support vessel deploying a HUGIN Endurance,” he says. “The fact that this AUV can operate for 15 days means that a support ship can be released to attend to other matters, which is a more cost-effective use of its time. In addition, recovery in heavy seas can be hazardous, so the simple fact that the AUV can stay down for far longer greatly reduces the risks associated with launch and recovery in challenging conditions.”

The HUGIN Endurance is, of necessity, a substantial piece of equipment – 33 feet long and four feet in diameter – but it can nevertheless be transported in a standard-size shipping container. In shore-to-shore applications, dockside cranes would convey the AUV to and from the water, but a support vessel equipped with Kongsberg Maritime’s heavy-duty Launch and Recovery System (LARS), essentially a cradle operating from midships, could also handle the process.

A game-changer for energy?

An AUV with such an extended range has countless possible applications, but a key area in which Kongsberg Maritime see the HUGIN Endurance making an immediate difference is in wind farm and energy platform surveys. “Removing the traditional survey vessel makes AUVs a low-carbon option for a survey,” Richard explains. “Commercial operators have often shied away from using AUVs in shallow water, but actually the HUGIN Endurance is not only capable of doing it, but it’s more productive doing it this way than with a traditional surface-mounted multibeam. We can demonstrate that quite clearly, even in 100-130 feet of water.”

An example of a potential survey where HUGIN Endurance would demonstrate a clear advantage would be the Beatrice wind farm, comprising 84 turbines off the coast of Wick in the north of Scotland. There are four further areas nearby which have been highlighted for expansion. The AUV would be launched from shore and fly at an altitude of 100 feet with a sensor range of approximately 800 feet either side, giving a total swath of 1600 feet.

“If you look at the productivity measure and the cost per day of surveying the Beatrice field, which has 150 feet of water depth, with a surface-mounted multibeam,” Richard comments, “we can be about 50 percent faster. That means HUGIN Endurance can cover the whole survey area in about nine days, including transit from shore. It would take a surface-mounted multibeam about 14 or 15 days to do the same area.”

Innovation from experience

The HUGIN Endurance is hard proof that the HUGIN range has come a long way since the earliest days of its joint development by KONGSBERG, Statoil and the Norwegian Defence Research Establishment (FFI) back in 1991. As a pioneer in the large-diameter AUV category, it simultaneously has a wealth of field experience behind it – HUGIN models have completed more line kilometers than any other survey-class AUV – and tacitly carries the responsibility of upholding Kongsberg Maritime’s corporate reputation for driving innovation in the sphere of underwater robotic technology.

Externally, the HUGIN Endurance’s profile will be instantly recognizable to anyone familiar with the other models in the HUGIN range. Closer scrutiny, however, reveals several new features. Its tail design, for example, accommodates contra-rotating dual propellers which will take the AUV to a speed of eight knots while also providing a fallback solution in the event of one prop failing. “This is a lot faster than the norm for AUVs,” Richard points out, “although the optimum survey speed is probably between four to six knots. The resolution is constant because we oversaturate the survey area with sound transmissions.”

Swept fins wrap over the tips of the blades for protection, while the new shape and increased surface area of the aft planes will reduce drag. Meanwhile, the design of the forward fins is intended to enhance the quality and accuracy of high-resolution data gathering by improving roll stability, reducing the turn radius, keeping the AUV level and preventing the tail from dropping when commencing a climb close to the seabed. Additionally, slow-speed manoeuvring fins equipped with thrusters have been installed to reinforce handling at speeds below one knot.

A wealth of information

Given its generous proportions, it stands to reason that the HUGIN Endurance is capable of accommodating a hefty sensor payload for wide-swath bathymetry. Kongsberg Maritime points out that numerous configurations of active and passive sonars are available, but interested parties can expect the AUV to be equipped as standard with units including a HISAS 1032 dual Rx SAS (synthetic aperture sonar), an EM2040 0.7° dual Rx multibeam echo sounder, a cNODE transponder for positioning and communications, sub-bottom profiling system, a UHD camera and laser, and sensors to ascertain factors such as conductivity, temperature, depth, methane and CO2 levels. A forward-looking sonar in the nose of the AUV scans both vertically and horizontally to assist with situational awareness.

The AUV is designed to enable remote operation via integration with the Kognifai open digital ecosystem or third-party data platforms, and KONGSBERG’s Maritime Broadband Radio (MBR) facilitates secure communications with the remote operating center to report status and receive mission updates. A retractable mast hosts the MBR and RF antennas, together with surface awareness sensors – GNSS, AIS and cameras – to assist in marine traffic avoidance.

Navigational certainty underwater is maintained by the company’s Sunstone inertial navigation system – a key enabling technology for autonomous long-range operations. This takes input from a depth sensor, compass, a Kongsberg Seatex MGCR5 IMU Inertial Measurement Unit (IMU) and a Doppler Velocity Log (DVL). The in-situ performance depends on the configuration and can be better than 0.01 percent of distance travelled.

Fully equipped with redundancy and in-mission processing, the HUGIN Endurance also incorporates Reflection post-mission analysis software – capable of being hosted on a local network or in the cloud – which collates and displays all AUV data in a single software package.

“The HUGIN Endurance generates much more information, faster and more cost-effectively, than you’ll get from a surface-mounted multibeam,” Richard points out, “so you’ll not only get the bathymetry, but also very high-resolution seafloor SAS imagery and the oceanography profile across an entire area. This could be up to 320 square nautical miles in a single dive, depending on payload configuration and altitude. In addition, you could get data revealing things like leaks or seeps or bubbles in the water column. Furthermore, because we carry a sub-bottom profiler, you won’t just get what’s in the water and on the seabed, but also what’s beneath the seabed.”

With its ability to be put to work in a variety of geophysical, environmental, hydrographic, naval and SAR applications, the HUGIN Endurance appears destined to make a definite impression in a range of markets.

This post is sponsored by Kongsberg Maritime.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.