The Rise and Decline of Kinetic-Hydraulic Power

Some 10 years ago, there was great interest in kinetic free flow turbines able to generate electric power from rivers, ocean currents and tidal currents as well as from coastal ocean wave conversion. While still being considered in some regions, interest in the technology has declined.

Introduction

The practice of converting power of rivers to mechanical work dates back over some 4,000 years to Ancient Greece, when innovative people built a mechanism to use river energy to convert grain such as wheat into flour to make bread. Over the millennia and centuries that followed, inventors improved on the river-powered waterwheel and used the energy to do a variety of task such as driving saws to convert logs into planks, grind whole grains into flour and drive lathes, drills, looms and a variety of human and animal powered tools of production.

The waterwheel was usually supported by a massive driveshaft that protruded from a building that had been constructed at the river’s edge and where river water flowed fast. During operation, only a small section of the waterwheel was submerged as it rotated under the force of river power. A variation built at waterfalls involved flowing water from higher elevation over the top of the wheel. The year 1812 saw the development of the wholly submerged Francis Turbine where a fast flow of water from higher elevation exerted force on blades built around the entire wheel and delivered much greater power.

Kinetic Turbines

The ongoing search for low-cost renewable energy led to the development of the submerged 3-bladed windmill suspended from overhead from a boat hull. Given that water has a density some 850-times that of air, a slow flow of river water of just over two meters per second (six feet/second) generated electric power from a comparatively small diameter three-bladed turbine. As the technology began to show future promise and governments made easy research and product development funding available, a variety of competing, entirely submerged kinetic turbine configurations appeared that involved parallel-axis, transverse-axis and vertical-axis variants.

A few governments were actually willing to invest money into installations in fast river streams. One installation along the St Lawrence River near Montreal involved a ducted 100mW turbine assembly weighing 120 tonnes that had to be lowered to the river floor in water flowing at seven knots. It was during real world service that some kinetic turbines revealed their shortcomings that included breakage of turbine blades as water speed increased to 11 knots. Undertaking repair and maintenance on submerged turbines required their removal from the river, at high expense and to the point of making large and heavy turbines economically unattractive.

Power Output – River vs Wind

A study undertaken in 2015 by the Eastern Canadian power utility Hydro Quebec revealed that kinetic turbine have to be relatively small, installed in comparatively shallow water and will rarely generate more than 400kW in river currents flowing at 4.5m/s. Due to the lower density of the working medium (air vs water) by a factor of 850, wind turbines installed on towers placed on hills can be built with rotor diameters that exceed 150m or over 500-feet and generate power with air flowing at 50 to 60km/hour (14 to 16.7-m/s).

The power output varies to the cube of the speed or 91 for river current and 3,375 for wind blowing at 15m/s. Wind turbine rotors can be built to 200m diameter or 30 to 40 times the rotor diameter of kinetic turbines, 3375 x 30 x 1/850 = 120 times the power output of a single river turbine. The largest wind turbine being built by General Electric is rated at 12MW, or the output of 30 river turbines. Power utilities seek technology where for a given capital and installation coast, a single installation delivers massive power output.

Cost Competitiveness

The combined capital, installation and long-term maintenance cost of a farm of 30 river turbines on the river floor in fast flowing water current, will greatly exceed that of a single large wind turbine and especially in regions where wind is frequent and reliable. In Canada, there are over 1,000 small islands on the eastern side of Hudson Bay near the coast of Quebec, where future wind turbines may be installed to convert energy from frequent and powerful winter winds. The greatest concentration of tidal kinetic energy in the world occurs on the western exit of Hudson Strait in Canada.

Tidal Power Dams

However, due to the limitations of kinetic hydraulic technology, it is very unlikely that there will be any development of hydrokinetic tidal energy at either west end or eastern end of Hudson Strait. The tidal power stations built at Rance in France and at Annapolis in Canada are essentially hydroelectric power dams that generate electric power from the different in height of water levels between ocean and a river confluence. The Annapolis tidal power station delivers an average four to five hours of 20MW electrical output while since 1964, the Rance tidal power station delivers 240MW of electrical output.

Ocean tidal dam power is reliable and predictable and over time, proving itself to be cost competitive against wind power. The concept of a dam can be expanded upon and adapted for use with ocean waves and with fast flowing water currents, using an approach first developed over 1,000 years ago by the engineers of the Mayan Empire, who diverted water from fast flowing river current into specially excavated tunnels of steadily decreasing cross sectional area, then made the water to appear to flow uphill to water “keeps” built into nearby hill-based Mayan enclaves.

Coastal “Blow-Holes”

The erosion effects of ocean waves along rocky coastlines can over greatly extended periods of time, carve submerged caverns into the rock and at times, the erosion can break through to the surface. A portion of the incoming wave energy enters the cavern and blasts upward to high elevation above sea level from the blow hole. Such phenomenon may have inspired the Mayan engineers to develop special tunnels to divert fast flowing water current to travel underground to higher elevation and to an underground storage chamber carved into the ground under a hill located near the river.

Several inventors and entrepreneurs have applied the “blow-hole” approach to direct a portion of ocean wave energy into elevated coastal storage reservoirs built above sea level. Seawater returns to the ocean by passing through a low-head turbine that drives electrical generating gear. While not the most efficient method by which to convert ocean wave energy to electric power, all machinery using the coastal reservoir method is located at the coast where it is easy to access, maintain and repair. More efficient offshore energy conversion technology often involves higher cost, higher complexity and greater difficulty maintaining and repairing the equipment.

Moving Water Upward

The design of some breakwaters converts incoming waves to sprays of water that blast upward. On a fast flowing section of river, a large waterwheel driving a small water pump can use the kinetic energy of the water to transfer a percentage of the water stream to higher elevation, except that the Mayan engineers achieved the same result without using waterwheels or mechanical pumps. A venturi-pump operating in reverse mode also has the potential to use the kinetic energy of a fast flowing water stream to transfer a percentage of the stream to higher elevation reservoir.

Without using any moving parts, a reverse venturi-pump involves a converging and diverging section of duct, with the inlet having greater cross-sectional area than the outlet. As the flowing water enters the duct inlet, decreasing cross-sectional area causes it to accelerate to higher flow speed. At the small throat section, up to 30 percent of the water would flow into the inlet of a pipe that would transfer it to a coastal reservoir at higher elevation. The remaining water would flow into the diverging section of duct and to the outlet before re-entering the river.

Extreme Low-Head Turbines

An extreme low-head turbine developed in Germany can generate electric power at over 70 percent efficiency from water flowing from a reservoir over a height difference of 0.75m. While the construction of a small coastal reservoir would incur some expense, the machinery that would produce the electric power would be easily accessible for purposes of regular maintenance and repair. Several reverse venturi-pumps that would require minimal maintenance and upkeep could supply water into a single reservoir. The approach could be designed to work along fast flowing sections of river or source water from coastal sea waves.

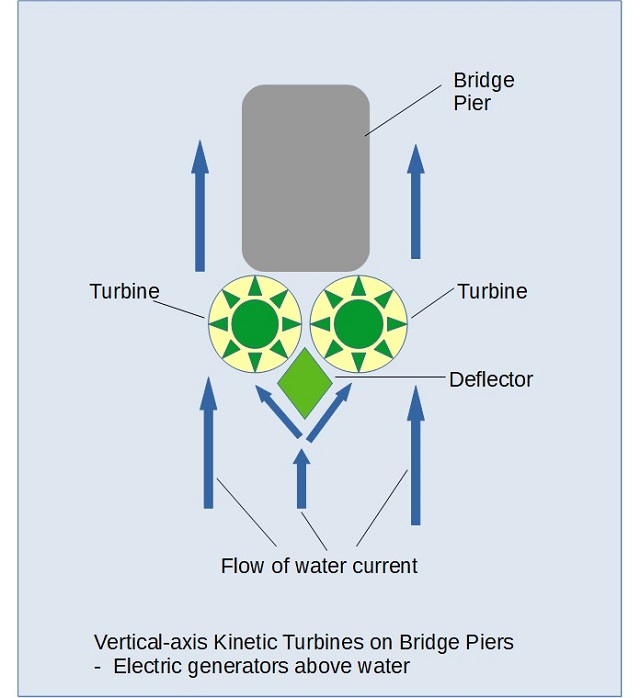

River Bridge Piers

Across many rivers internationally, newer bridges replaced older bridges except that the piers of the original bridges often remained in place, usually cut down in height to just above the water level. Bridge piers are designed to withstand extreme vertical and lateral loadings, even if stacks of submerged vertical-axis kinetic hydraulic turbines were secured to the piers between the river floor and just below river surface. Retired and in service bridge piers offer a method by which to lower the cost of installing groups of multiple vertically-stacked turbines into rivers and drive electrical equipment installed above water.

Bridge piers may serve as anchor points for floating vessels built with kinetic turbines under the hulls, with electric generators installed inside the hull. Each pier may serve a dual purpose of having turbines secured directly to it and be the anchor for a downstream vessel equipped with hydraulic turbines. Piers in deep channels that extend to river floors some 50 feet depth could carry vertical stacks of vertical axis turbines to generate 250kW on each side of each pier, with turbine working sections protruding beyond the width of the pier and into the fast flowing current.

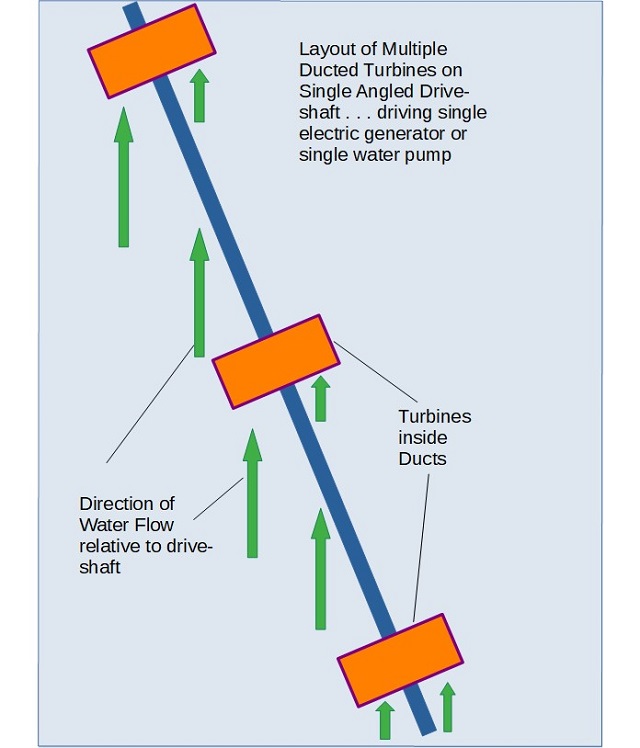

Multi-Turbine Single Shaft

In maritime history, Sir Charles Parsons built the high-speed steam turbine boat called Turbinia that features an extended length, downward angled propeller shaft with several small propellers spaced at regular intervals. The multi-prop on single shaft method reduced propeller cavitation and allowed the boat to become the fast boat of its period. In California, wind turbine builder Douglas Selsam has built several installations where multiple turbines are secured to an extended length power shaft that drives a generator and is set at an angle to the prevailing wind, to keep each successive out of the shadow of the upstream turbine.

The Selsam approach has proven itself with small diameter wind turbines and offers a method by which to install multiple hydraulic kinetic turbines on a single, extended length power shaft perhaps supported from overhead by a truss and one or more floating vessels. Installation options would include fast flowing water current in a comparatively shallow non-navigable stream or installed below navigation depth along a fast flowing navigable stream. There may be scope to install ducts around each turbine to enhance efficiency. The multi-turbine on single angled shaft approach offers the potential of higher power output at reduced capital cost.

Stronger Turbines on Super-shaft

Fast flowing current such as occurs in channels around Canada’s Bay of Fundy has destroyed the blades of several propeller type turbines. Installing such turbines along an extended length power shaft like the Selsam system offers the possibility of also installing structural bracing to enable each turbine to endure operation in fast water current. A cable secured to an upstream anchor point would connect via bearings each turbine shaft and each turbine duct which would house bearings, against which each turbine outer radius would ride, giving turbine blades greater strength to withstand powerful water currents.

Arranging a pair of multi-rotor super-shafts in a V-shape configuration would double total power output. The super-shaft extended length in V-configuration can allow for several levels of turbines to further increase power output. A single shaft with 8-turbines of 250kW output could deliver 2MW of output and 4MW in a V-shape layout, with four levels of turbines delivering up to 16MW of possible output. Selsam’s extended length power shaft with multiple rotors is well proven in wind power conversion and offers potential to generate commercial levels of electric power in water currents, using multi-level V-shaped layouts.

Future Research

Future research would need to develop methods by which to reduce the capital, installation and long term operating and maintenance cost of kinetic hydraulic power conversion. It appears possible to attach pairs of stacks of vertical-axis turbines to protrude into the river current on either side of bridge piers, a possible method of reducing capital, installation along with long-term operating and maintenance cost of the turbines. Installing multiple turbines along a single length power shaft suspended from overhead is another possible method by which to increase output at competitive costs.

Research will be required into optimizing the operation of reversed venturi water pumps intended to use fast flowing water current to transfer a percentage of the water higher elevation into nearby coastal reservoirs. The same approach could transfer a percentage of water from incoming ocean waves to higher elevation coastal reservoirs to sustain operation of super low-head turbines. At the present time, the low amount of power available from kinetic turbines makes the technology useful at remote locations with small populations. To function competitively near large populations requires greatly increased power output and more competitive coasts.

Conclusions

There is potential scope to revise the approach by which electrical energy is produced from kinetic hydraulic energy, with the objective of increasing power output while reducing capital, installation and long-term maintenance costs of the conversion technology. Additional information on multi-rotor turbines is available at www.selsam.com

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.