Compressed Air Over Water for Short Distance Propulsion

During the early to mid 1900s, manufacturers of steam locomotives also built compressed air powered locomotives for the mining sector. While battery electric propulsion has replaced compressed air locomotives, the hobby sector has developed advances in compressed air propulsion that involve air over water operation. There is potential application for compressed air over water propulsion in modern day short distance maritime propulsion.

Introduction

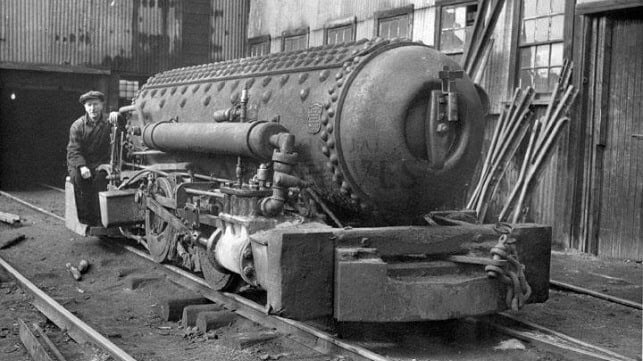

Classical energy storage included compressed air powered locomotives for the mining sector, the last of which were built during the 1950s and involved the use of high pressure tanks pumped to 3,500 psi (pounds force per square inch) and air density at 14 pounds per cubic foot. Operating the tanks between 1,000 psi and 3,500 psi would have raised air temperature to over 300 deg F or 155 deg C, allowing for heat storage by surrounding the air tanks with heavy insulation. The high-pressure technology was well suited for short distance operation.

Builders of model rockets develop compressed air over water propulsion to accelerate scale model rockets made from plastic soft drink bottles, sending them skyward. A related experiment involved compressed air over hydraulic propulsion technology to repeatedly accelerate a city transport bus from standstill. The physical scale of some maritime vessels combines massive weight carrying capacity with generous volumetric space, allowing for installation of energy storage and propulsion technologies that would be unsuitable for railway or road vehicle operation. Such modified compressed air has potential in short distance ferry and dockyard tugboat operation.

Compressed Air Propulsion

Compressed air propulsion is well proven in mining locomotives, with power output being dependant on the combination of air pressure and air mass flow rate through the cylinders. Compressed air at 1,000 psi pressure at room temperature has a density of 5 pounds per cubic foot. While bottle rockets that use air over water propulsion compress air density to less than 1 pound per cubic foot, the air exerts pressure on water having a density of 62.4 pounds per cubic foot, greatly increasing mass flow rate through the rocket nozzle and potentially through an engine that operates on compressed air over water propulsion.

Pumping air to high pressure produces heat and especially if there is a large difference between lower and upper pressure. Minimizing the difference between lower and upper temperature reduces the build up of heat, reducing thermal stress on energy storage tanks. To charge the system, air would initially be pumped from atmospheric pressure to 500 psi (34 atm), then cooled to room temperature of around 80 def F or 25 deg C. Subsequent charging would raise stored air pressure to 1,000 psi or 68 to 70 atm, with heat build of up to 200 deg F or 96 deg C, minimizing thermal stresses.

Ground Effect Plane

Bottle rockets have reached elevations of over 2,700 feet and more recently over 5,300 feet in 2024 involving a 2 stage bottle rocket. A large scale model ground effect plane carrying water tanks and operating air pressure tanks between 1,000 psi and 500 psi would theoretically travel several miles above water, between islands or between a mainland and an offshore island. Recharge would involve electrically powered or gravity powered high pressure water pumps operating between 500 psi and 1,000 psi, to transfer filtered water into high pressure onboard water tanks. A land based catapult system would launch the plane into ground effect flight mode, with water jet subsequently providing propulsion over several miles.

The ground effect plane might operate as a radio-controlled or computer-controlled drone that carries small parcels between islands, between a mainland and an offshore island, across the entrance of a large bay or across a narrow lake. An electrically driven winch cable would be capable of accelerating a larger-scale ground effect plane across a smooth, solid surface to lift off speed, when water jet propulsion would blend in to sustain propulsion. At the destination end of the trip, touch down might occur on water or if a suitable coastal runway were available, touch down on land.

Ferry Boat

A boat using air over water propulsion would operate over the same pressure range as the concept ground effect plane, except that a low volume mass flow rate of high pressure water would drive a variable pitch propeller via a hydraulic motor. Converting the high speed water jet of low volume flow rate to a massive volume of water being pumped rearward at much lower speed, greatly increases propulsive efficiency. High water pressure water flow initially entering the hydraulic motor would be able to accelerate the vessel to sufficiently high speed to ride up on to hydrofoils, reducing drag and extending travel range.

A comparatively small ferry vessel operating on compressed air over water storage would operate on hydrofoils, in passenger service. In slow freight service, the hull of a vessel built to 450 feet length by 50 feet width would house multiple high pressure air tanks along with multiple high pressure water tanks. Massive volumes of filtered water would need to be available at both ends of the trip, to assure rapid high pressure recharge during layovers. Such a vessel would operate short distance ferry services carrying passengers, or be assigned to extreme short distance short sea shipping transferring freight between nearby port terminals.

Tug Boat

Compressed air over water propulsion offers potential application in dockyard tugboat operation, where a short duration rapid burst of propulsive power would be required to accelerate large ships over short distances. A dual power tug would combine a lower power propulsion system for sailing around a dockyard and terminal area, with the compressed air over water propulsion technology being exclusively used when required to accelerate and move large, heavy vessels over short time duration.

that matters most

Get the latest maritime news delivered to your inbox daily.

Conclusions

While compressed air propulsion is well proven in short distance railway application, compressed air over water propulsion has been developed for aeronautical applications, where it has been proving itself. High pressure water driving hydraulic turbines is well proven in small site and large scale power dams. The fundamentals of the technology are well proven, allowing potential future application in short distance ferry boat services, short distance freight vessel service, tug boat service and short distance ground effect transportation. There is scope to undertake future research into further developing and refining compressed air over water technology for various propulsion applications.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.