NTSB: One Check Valve May Not Be Enough to Keep Your Vessel Afloat

An open overboard shutoff valve and a failed check valve led to the sinking of a laid-up towboat at a yard in New Orleans last year, the NTSB has concluded.

At about 0600 in the morning on June 25, 2023, an employee found the towboat Joanne Marie listing heavily and partially flooded at the Bollinger Quick Repair Shipyard outside New Orleans. The ship was in layup at the time, without power or crew, and no one was injured in the partial sinking.

The Joanne Marie was an occasional-use vessel for the operator, performing fleeting operations as needed and shutting down between jobs. On June 23, two days before the incident, the crew brought the towboat back to her customary layberth and tied up next to another towboat. The port captain came on board and helped with shutting down and buttoning up the boat for an indefinite stay. The procedure included tightening the shaft packing glands to no-drip, but fuel tank crossover valves and overboard shutoff valves were left open. This was a matter of routine practice and did not violate company procedure.

Early in the morning of June 25, a company employee noticed that Joanne Marie was listing heavily and called the port captain. The vessel was partly submerged at the stern, listing to port, and touching the bottom on the port quarter. (Luckily the canal was only 15 feet deep.)

Under the circumstances, the damage was relatively limited. Joanne Marie's port side was submerged up to the top of the main deck level, but the vessel was stable and had released only a few gallons of fuel into the environment. The crew plugged the fuel vents, and a heavy lift crane was called in to refloat the ship. By 1600 the same day, Joanne Marie was successfully refloated.

Both of Joanne Marie's main engines and diesel generators were damaged, along with some of her electrical equipment and her crew spaces. The cost of repair came to about $175,000.

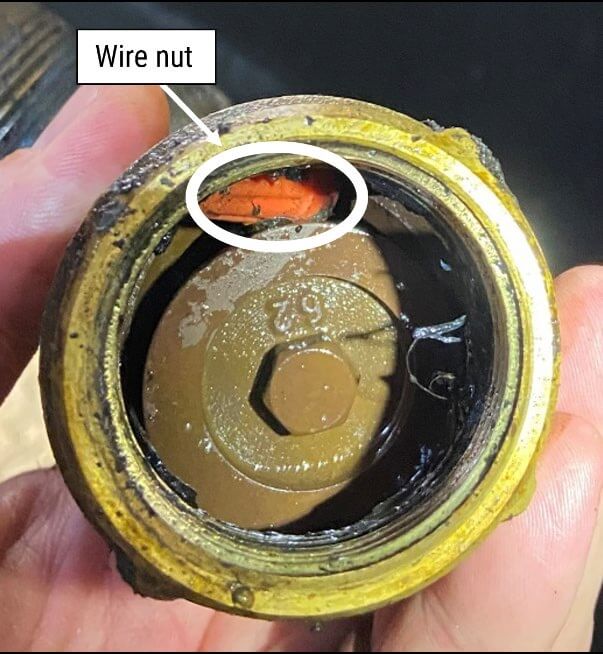

Investigators came aboard after the refloat to determine the cause of the sinking. The owner's surveyor used a hose to pressurize each discharge pipe from the outside, and found water leaking from the inlet strainer on the bilge pump on the starboard side cofferdam. The piping had a check valve between the pump and the overboard line, but when the company's engineers opened up the check valve to have a look, they found that an everyday orange wire nut (twist connector for electrical wires) had somehow gotten sucked into the pump and jammed the valve open. Since the ball valve on the discharge line had also been left open, there was nothing to prevent water from flowing backwards through the line, through the pump, and into the cofferdam.

The culprit: a simple plastic wire nut jamming open the check valve (USCG)

Ordinarily the discharge pipe was above water, but the vessel had more fuel in her tanks than normal, and was sitting about a foot lower than her usual operating draft - low enough that the discharge would have been at or near the waterline. Water from a passing vessel's wake or from a slight list likely flowed back through the line and flooded the engine room.

Since the boat had no power, her bilge pumps did not come on to counteract the flooding. Once the boat started to list, fuel would have flowed "downhill" from the starboard side tanks into the port side tanks through the open crossover valves, adding to the accumulation of mass on the low side of the boat.

that matters most

Get the latest maritime news delivered to your inbox daily.

Based on lessons-learned, the operator has modified their checklist for vessel layup to include closing the overboard discharge valve when the vessel has no power.

"To reduce the potential for flooding, operators should consider closing through-hull fitting valves," concluded NTSB. "Installing high-water bilge alarms and fire detection systems that remotely alert responsible personnel facilitates the early detection and mitigation of potential safety risks, such as flooding or fire."