Designed for Efficiency

If shipping is to decarbonize its operations, maximizing hull efficiency will be essential, and the only way to get there is through advanced engineering - particularly computational fluid dynamics (CFD).

Developed for aerospace applications and refined for use in naval architecture, advanced CFD modeling allows engineers to study the interactions of air and water with the exterior of the vessel. CFD is a big part of the magic behind modern racing yachts, like the gravity-defying America's Cup boats, and if used with skill it can improve the efficiency of a merchant ship design by as much as five percent.

CFD is a complex art, and while many larger naval architecture and engineering firms have a team in-house, others outsource it to a specialist with high-end methods. One specialized firm, Cape Horn Engineering, is applying CFD expertise honed in the yacht racing world to one of the most interesting questions in commercial shipping: how to put sails back on board merchant vessels.

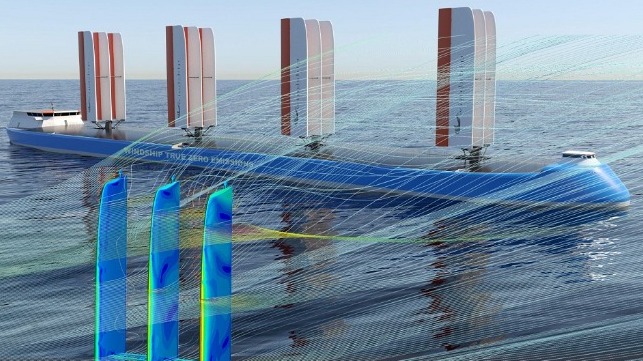

Cape Horn is part of the development team for the Windship Technology project, which aims to build a cargo vessel that uses solid wing sails for dramatic fuel savings. Existing wind-assisted propulsion systems like Flettner rotors and kite sails can reduce a vessel's fuel consumption by about 10 percent, according to the partnership, but Windship's three-masted rig is expected to achieve savings of 30 percent.

The solution, called Windship Auxiliary Sail Propulsion System (WASPS), uses three sets of solid wing sails to capture the wind's force. The structures are all designed with composite construction for light weight and durability, using technology sourced from the wind industry. The rig is stowable for operations in port.

Cape Horn's CFD business started at the America's Cup, where solid wing sails have been honed to an art. The company is bringing this experience to bear on the design and evaluation of the new Windship, including validating the technology's potential. Since a vessel and its sails function together, it is helpful to have a unified model that evaluates both simultaneously, the firm says - and this is something that CFD techniques can do.

"Currently, wind propulsion systems and ship design are considered as two entities, hence they are designed independently. It is reasonable to believe that they should be designed as a whole from the earliest stage, due to the dependency of each aspect on the other," said Cape Horn's managing director, Rodrigo Azcueta.

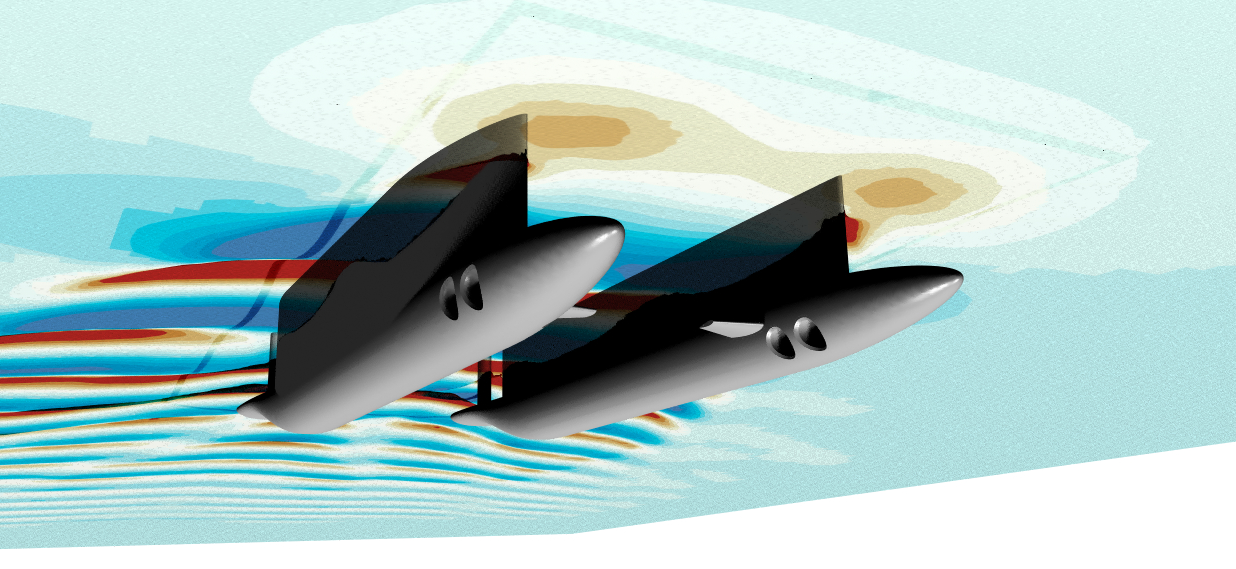

CFD expertise is also useful when analyzing novel or complex structures, like floating offshore wind turbine platforms or SWATH vessel designs. As the cost of computing power comes down, the possibility for more detailed and comprehensive model simulation goes up, along with certainty in the real-world performance the design will have when built. This has value for the vessel designer, the shipyard and the operator, according to Cape Horn.

As an example, the designer of a new SWATH hull vessel for offshore wind farm service needed to determine how best to design a stabilizer element to manage trim during transits. SWATH hulls tend to trim bow down when moving ahead at full speed, and the design specified a pair of stabilizers towards the bow in order to keep the vessel on an even keel. Complex CFD analysis made it possible to predict how the stabilizers would affect the vessel's trim at each angle and speed, allowing the OEM to design custom controls for the stabilizers based on predicted performance - even before the vessel was built.

that matters most

Get the latest maritime news delivered to your inbox daily.

Illustration courtesy Cape Horn Engineering