NGOs Critical of Fuel Efficiency Record

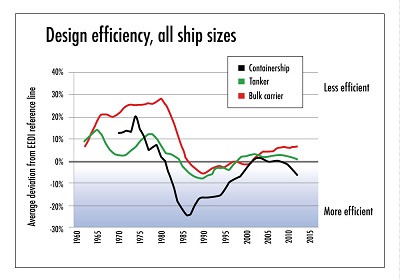

New ships built in 2013 were on average 10 percent less fuel-efficient than those built in 1990, according to a new study commissioned by Seas At Risk and Transport and Environment.

The study shows that container ships built 30 years ago already, on average, beat the Energy Efficiency Design Index standard that IMO has set for new ships built in 2020.

It also shows that bulk carriers, tankers, and container ships built in 2013 were on average 12, eight and eight percent less fuel efficient respectively than those built in 1990, a quarter of a century ago.

The deterioration of the efficiency after 1990 in bulkers was caused by an increase in main engine power, states the report. “In some size categories, speed also increased, but much less than can be accounted for by the power increase. Kristensen and Lützen have shown that the block coefficient has increased in this period, i.e. ships have become more box-like. At the same time, the length displacement ratio has decreased, so ships have become less slender. Both factors increase the resistance of the hull when moving through water.

Rational choices

The report states that fuel prices are a driver for efficiency improvements, but high freight rates can mitigate the signal by reducing the need to improve fuel efficiency for shipping companies and reducing the incentive for yards to offer innovative designs. Since most ships are ordered when freight rates are high, this combination of driver and barrier results in lower efficiency improvements than would occur without the freight rate counterincentive.

The report states that fuel prices are a driver for efficiency improvements, but high freight rates can mitigate the signal by reducing the need to improve fuel efficiency for shipping companies and reducing the incentive for yards to offer innovative designs. Since most ships are ordered when freight rates are high, this combination of driver and barrier results in lower efficiency improvements than would occur without the freight rate counterincentive.

“Even this short analysis points to a number of situations in which the choice for a less efficient ship would be rational:

• Ships that are designed for trades where length, breadth and draft are constrained face a trade-off between the capacity of a ship and the design efficiency because fuller ships are less fuel efficient. When freight rates are high, the additional profits that can be earned from a larger capacity may outweigh the higher fuel costs due to the fuller design. Hence, it can be rational to opt for a larger but less efficient ship.

• When freight rates are high, it may be attractive to have a ship as soon as possible. Since fuller ships require less time to build, in general, the benefits of having a ship sooner can outweigh the higher fuel consumption during the life of the ship.

• When labour costs and steel are expensive, the additional capital costs of a more efficient ship may not be earned back within a period that a shipowner would consider reasonable.”

The report continues: “In addition, there may specific circumstances under which yards and other stakeholders may not want to work towards building more efficient ships. For example, Mortenson (2009) points out that when the orderbooks are full, yards are reluctant to change standard designs. Under those circumstances, it is rational that they minimise the risk of time and cost overruns that are inevitably associated with innovative designs, because it would reduce the number of ships they can build and thus their profitability.”

So under some circumstances, like in the 1980s, this can lead to large, market driven improvements in design efficiency. In other circumstances, like in the 1990s and 2000s, this can lead to a deterioration of fuel efficiency.

Market Forces Not Enough

The findings contradict claims that shipping has been constantly improving its environmental performance, say the NGOs. They also demonstrate that market forces by themselves don’t result in more fuel efficient ships being built. Oil prices in the late 1980s and early 1990s, the time when new ships were historically most fuel efficient, were around a quarter of the levels seen in the 2008-2013 period (ca $25 vs $100 per barrel, in today’s prices).

The findings contradict claims that shipping has been constantly improving its environmental performance, say the NGOs. They also demonstrate that market forces by themselves don’t result in more fuel efficient ships being built. Oil prices in the late 1980s and early 1990s, the time when new ships were historically most fuel efficient, were around a quarter of the levels seen in the 2008-2013 period (ca $25 vs $100 per barrel, in today’s prices).

John Maggs, policy advisor at Seas At Risk and president of the Clean Shipping Coalition, said: “Now we know that we cannot rely on rising fuel prices, other market forces or the good intentions of industry to solve shipping’s climate problem. Instead we need a clear and ambitious target for reducing ship greenhouse gas emissions and legally binding measures to get us there.”

The IMO will review the stringency levels of its Energy Efficiency Design Index (EEDI) – the efficiency standards for new ships – during a meeting of its Marine Environmental Protection Committee (MEPC) in London next month.

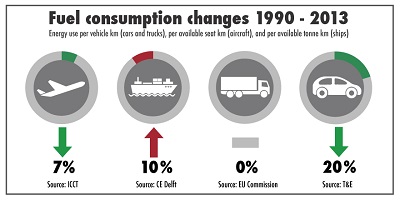

Bill Hemmings, clean shipping manager at Transport & Environment, said: “The truth is out! Aircraft and cars have become more fuel efficient, but despite a generation of technological improvements, ships have largely gone backwards for most of the past 25 years. The IMO’s design efficiency standard for new ships itself needs a redesign and strengthening if the standard is not supposed to merely bring us back to levels achieved 25 years ago.”

The report is available here.