Deep Sea Mining Simulator for Solwara 1

Nautilus Minerals has signed a contract with Tree C Technology for a simulator and a mining site monitoring system for the world’s first seafloor production system at Solwara 1 in Papua New Guinea.

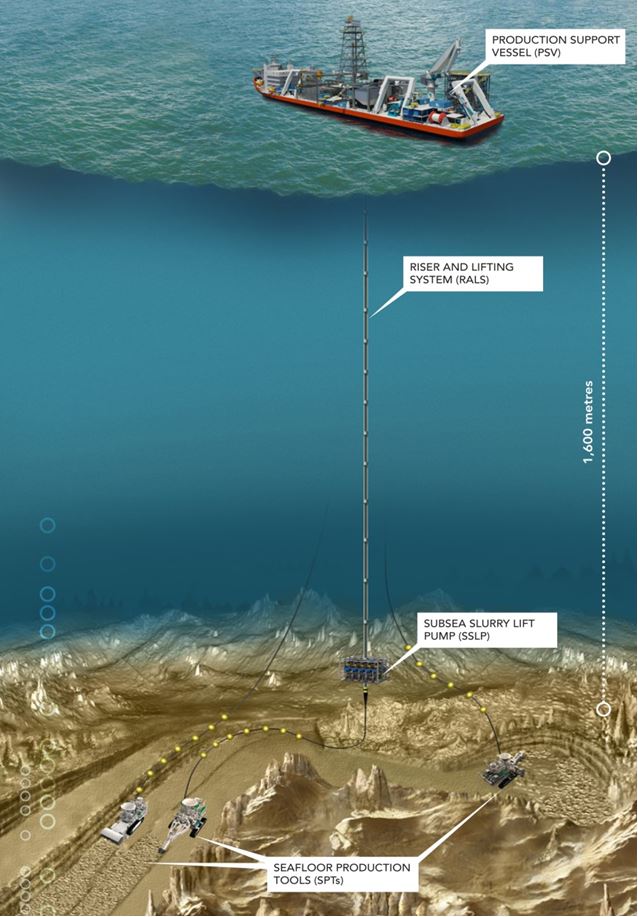

Solwara 1 is expected to be the world's first commercial high-grade seafloor copper-gold mine project. The mine site is approximately 30km (18 miles) from shore in the Bismarck Sea in around 1,600m (5,000 feet) of water. The site has indicated resources of one million tons grading 7.2 percent copper, five grams (0.18 ounces) of gold per ton, 23 grams (0.81 ounces) of silver and 0.4 percent zinc. Inferred resources add 1.5 million tons of 8.1 percent copper, 6.4 grams of gold, 34 grams of silver and 0.9 percent zinc.

The planned mining operation at Solwara 1 is the first of its kind, using bespoke designed equipment and a new remote control system designed specifically for the seafloor production tools (SPTs) that will be used.

The excavation and collection of mineralized material has been split into three individual tasks, which will each be carried out by a different seafloor production tool. The auxiliary cutter is designed as the pioneering tool which prepares the rugged sea bed for the more powerful bulk cutter. These two tools gather the excavated material; the third, the collecting machine, will collect the cut material by drawing it in as seawater slurry with internal pumps and pushing it through a flexible pipe to the subsea pump and on to the vessel via the riser and lifting system.

Successful execution of the mine plan is contingent on the safe and efficient manipulation of all of the elements of the seafloor production system. The simulator will enable operators to use the consoles and control software that will be used during the actual operation. The virtual environment will respond and behave as close as possible to the real world conditions at this depth requiring the best of simulation technology available today in terms of physics, hydrodynamic and wire dynamics engines.

Nautilus will employ an operations manager who will take overall responsibility for coordination of the seafloor production system. The Tree C developed mining site monitoring system will be a critical tool that shows a simulated but actual view of the subsea mining assets and surface support assets in real-time. The operations manager will direct all SPT and equipment moves based on the monitoring system since there will be no visibility due to turbidity and lack of light at this depth.

The simulator is based on the actual control systems and consoles that will be used and is built within a 30-foot container. Delivery is scheduled for the first half of 2017.

It is anticipated that the proposed Solwara 1 project will commence operations in the first half of 2018 subject to project financing and completion of the company's seafloor production equipment and vessel. The production support vessel is being built in China by Fujian Mawei Shipbuilding.

that matters most

Get the latest maritime news delivered to your inbox daily.

When completed, the vessel will measure 227m (750 feet) in length and 40m (130 feet) in width with accommodation for up to 180 people and generate approximately 31MW of power. All of the below deck mining equipment will be installed in the vessel during the build process to minimize the equipment integration to be completed following delivery of the vessel. The vessel is expected to be delivered by the end of 2017.