Hull-Sail Ship Readying for Tank Tests

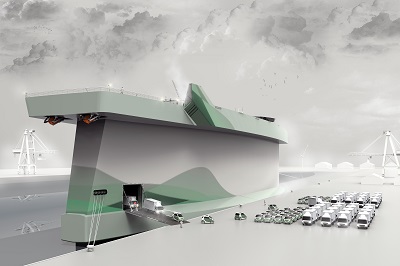

Terje Lade, creator of Project Vindskip, speaks about the drivers behind the development of his avant-garde car carrier design that could save up to 60 percent on fuel costs:

What were the drivers behind the development of Project Vindskip?

Much of the industry’s desire in the past had been associated with what I call ‘greed for speed’. In particular, I had been working on the design of speed sailing vessels in my spare time for many years where the objective was very much centered upon maximum speed for a given sail area. Over time, this ‘greed for speed’ was gradually being replaced by a growing concern for the environment and the possible impacts the maritime industry was having on our planet, as well as an increasing need to look at developing more fuel efficient designs.

Where did you take your inspiration from?

I often describe Vindskip as a cross between sailing and flying on water. Inspired by the aerospace industry and sailboat environment where the relative wind is a crucial factor in designing aircrafts, propellers and sailing boats, Vindskip is designed to exploit the wind for propulsion. For the construction of commercial vessels, this is a revolutionary way of thinking.

What are the unique aspects of this project?

What are the unique aspects of this project?

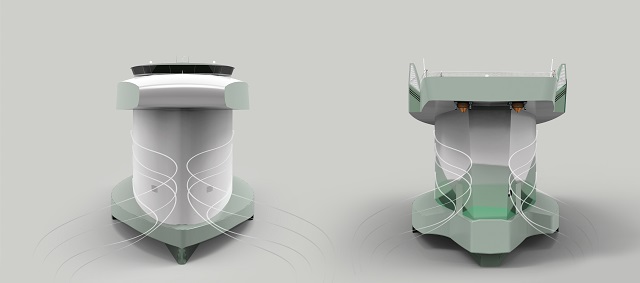

The concept is so simple you don’t even have to really think about it. True wind is the wind measured on board a stationary ship. When the ship starts moving, the so-called relative wind is being generated or in other words, the apparent wind measured on board a ship. A merchant vessel travelling at an average speed of 17 – 18 knots for example will have a headwind more than 50 percent of the time, regardless of the course it is taking. This in turn will cause a great drag force from the wind. The wind power system of Vindskip utilizes this apparent wind and generates a positive force in the longitudinal direction of the ship as a function of the angle of attack. In addition, the vessel has an LNG-powered propulsion system. Starting the ship from zero, one can exploit the aerodynamic lift generated to create speed and save fuel, therefore it becomes a dynamic system keeping a constant speed on the ship through a cruise control.

What technical challenges did you have to overcome?

For a merchant vessel turning the negative drag forces from the wind into a positive pull created some design challenges. Even though a vessel with a hull shaped like a symmetrical air foil travelling in the relative wind will generate an aerodynamic lift, it does not necessarily follow that the design will generate a positive pull in the ship’s speed direction. The first wind tunnel test we conducted clearly demonstrated this. We had to then look at generating a two-dimensional flow alongside the above water hull in order to achieve this. Recent wind tunnel tests at Cranfield University, as well as CFD optimization testing has helped us to improve the performance where we are now seeing a positive pull in a sector from 18 to 180 degrees apparent wind angle of attack, which is an incredible achievement. This year we will look at performing further CFD optimization tests for the underwater hull and subsequent tests in a model tank.

Why is it so important to develop these types of projects?

Stakeholders globally are recognizing the importance of creating more sustainable solutions to help address the ongoing environmental issues we as a planet face. This is evident through the introduction of new or amended regulations for the marine environment such as MARPOL Annex VI. Furthermore, Emission Control Areas (ECAs) are being introduced to help reduce emissions of SOx. Due to its very low fuel consumption, Vindskip can utilize LNG as fuel and will be capable of 70 days of steaming, worst case, between bunkering.

How long would it take to build and how much would it cost?

It will take another year to finish the Vindskip development project and we would estimate engineering and build will take approximately two years. Regarding costs, it’s hard to say at this stage as we’ve not yet received an offer from a shipyard. However, what I would say is that the estimated cost would not be that different of existing vessels due to the fact that the propulsion machinery required will be smaller than that of today’s vessels.

Source: Focus Magazine June 2014, BMT Group