2014 in Review: Ballast Water Treatment Monitoring

The 2004 IMO Ballast Water Management Convention has inched closer to entry into force over 2014. Japan and Turkey were among those states to ratify, and one or two of the major flags (e.g. Italy, UK, Singapore, China, Hong Kong, Bahamas, Malta, Greece, Cyprus) would be enough to end the 10 year wait. Equipment manufacturers, at least, hope 2015 will be the year.

Around 60,000 ships worldwide are expected to have to install ballast water treatment systems in the next five to seven years to comply with the convention. As shipowners are faced with the challenges of a convention that is growing in complexity with time, so are innovators seeing opportunities to help.

Now, a new breed of innovators is entering the scene. With an abundance of ballast water treatment systems on the market, shipowners are facing the challenge of understanding and perhaps installing compliance testing equipment to monitor them.

Draft guidance on self-monitoring for ballast water management systems was submitted to IMO by Germany and the Republic of Korea in October. The guidance states that monitoring systems should record operational parameters such as periods of uptake, discharge, warming up, shutdown, bypass valve status and filter cleaning events.

Ballast pump operation and flow rate at system outlet should also be recorded, along with a range of variables that will vary according to treatment type. For example, electrolysis systems should measure and record water conductivity or salinity, water temperature and total residual oxidant concentration at discharge. UV systems should record UV Transmittance or UV dosage and UV-sensor values at each reactor.

Amongst the innovators is a Danish company that has developed a unique system for measuring the quality of ballast water on ships. The monitoring carried out in real time during treatment, and it includes all of the water in the ballast tanks and not only a few, very small samples.

A ready-to-install prototype of the system, bw-monitor, was presented by the CEO of Ballast Water Monitoring, Frank Stuer-Lauridsen, at the 7th International Conference and Exhibition on Ballast Water Treatment 2014, held in Singapore. “Our monitoring system ensures a logged verification of the water quality which can be shared with authorities and reduce the risk of being detained by port state control for failing to comply with the IMO ballast water discharge requirements,” said Stuer-Lauridsen.

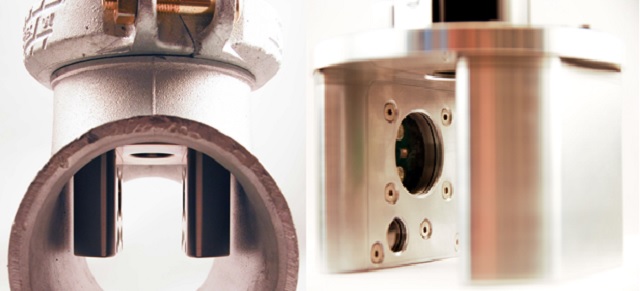

The system works in-line and on time, as it is based on automatic shipboard data sampling and analysis of all the ballast water before and after treatments. The biologic effect of the water management is measured, using a state-of-the-art method, developed specifically for the bw-monitor system, and involving laser light scattering, LED induced fluorescence and data driven extraction of information about the biological content. The focus is on filter performance and phyto-plankton viability.

“Our system presents a new approach. Other known ballast water monitoring systems are measuring water quality only after treatment, and only a few, very small samples. Another upside regarding our system is the potential for process control,” says Stuer-Lauridsen. He expects the bw-monitor system to be ready for market introduction in a matter of 6-12 months.

Cambridge UK based Bactest, inventor and manufacturer of Speedy Breedy, says a rapid portable test to show the efficacy of a treatment will be important for both shipowners and port state control.

Speedy Breedy has been trialled many times in a variety of liquids to include potable water, ballast water, process water and many other liquids including food and beverages. The system has also been trialled by ballast water treatment equipment vendors.

The number of ballast water samples to be tested has not been definitely specified yet, says

Professor Annie Brooking, CEO of Bactest, but tests have shown that at least two samples are needed to get a representative sample which is required by IMO. It is likely that samples will be taken at the start, middle and end of the decontamination process to show that it has been effective throughout.

“It is in the interests of the operator to prove efficacy of their system. The IMO D2 standard sets out tests for 3 bacteria: E.Coli, Enterococci and Vibrio Cholera. Speedy Breedy is the only instrument that is able to test for these three bacteria that is suitable to be used on a ship or in a port. Speedy Breedy does not require experts to run the test or interpret test results,” says Brooking.

Speedy Breedy protocols have been developed for both fresh water and seawater testing. These protocols are used in conjunction with selective media which is provided ready filled in the test vessel, so the operator simply adds a sample to the test vessel and starts the test.

Ballast water regulation standards (US and IMO) are expected to require ballast water treatment systems to reduce contamination of Enterococci to < 100 cfu per 100 ml and E. coli to < 250 cfu per 100 ml. Speedy Breedy protocols are therefore designed to allow enumeration of these organisms at a range that is appropriate to these standards and differentiate compliance from non-compliance. “Speedy Breedy is very accurate and sensitive being able to detect a single organism,” she says.

The number of manufacturers entering the market is growing. Chelsea Technology Group is developing FastBallast, a Fast Repetition Rate fluorometer, which is designed for installation into ballast water treatment systems or ballast tanks. Most recently, UK-based Memteq has said that anticipates development of a new system called Aquagard SED (Sample Elute Detect) in 2015. More companies are expected to follow, applying their sterilization or condition monitoring technologies to this new challenge or engineering new solutions from a scientific background.

IMO continues to clarify what will eventually be required. Also submitted to IMO in October was the first draft of manual entitled: Ballast Water Management: How to do it. The manual was submitted by IMarEST, and provides advice on the process of ratification, implementation and enforcement of the convention. It is designed for governments, shipowners, port state control and other stakeholders and states that an effective compliance programme should incorporate all of the following elements:

1. compliance monitoring through routine inspections

2. reporting procedures

3. adequate investigations of violations reported or otherwise detected

4. a system of adequate sanctions in respect of violations

5. education and public awareness programs and

6. cooperation and coordination with other parties.

The type of sanctions applicable to varying violations under the convention will be determined by each flag state and may be a function of several legal, political and economic circumstances. However, the idea is to have harmony between neighbouring states so no one state offers a safe haven. On the other hand, sanctions may take voluntary mitigation efforts and self-reporting into account, thus creating an incentive for shipowners to invest in monitoring equipment as well as a treatment system.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.