Newcastlemax LNG-Fuelled Bulker Design Ready

Project partners BHP, Fortescue, Mitsui O.S.K. Lines (MOL), Rio Tinto, SDARI, U-Ming, Woodside, and DNV GL have demonstrated the commercial potential and technical feasibility of LNG-fuelled bulkers in a "green corridor" iron ore and coal trade between Australia and China.

The result of the project is an LNG-fuelled Newcastlemax design which is in the process of receiving Approval in Principle from DNV GL.

The idea of developing LNG-fuelling infrastructure for the vessels operating on the Australia–China iron ore and coal trade route has been contemplated by major charterers, shipowners and operators for many years. As LNG production has climbed, especially in Australia, and in recognition of the upcoming IMO restrictions on sulfur emissions, the option of LNG as a single-system solution for emissions compliance has become ever more attractive.

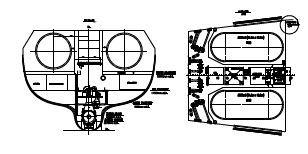

Chinese ship designer SDARI developed the design of the 210,000 dwt Newcastlemax bulk carrier based on their highly energy efficient Green Dolphin design. Dual fuel engines were quickly decided upon by the project partners, as this is a mature technology with multiple suppliers offering solutions and the dual fuel design providing operational redundancy.

Based on fuel consumption analyses, an LNG fuel tank size of approximately 6,000 cubic meters was found to be optimal, with bunkering in Australia for the round-trip. Several locations for the LNG fuel tank were considered, and finally the optimal solution was found – with the two LNG fuel tanks placed directly above the engine room and submerged a few meters below the main deck. This innovative design offers protection for the fuel tanks, enhances fire protection and does not reduce the cargo carrying capacity, even for volumetric cargoes such as coal.

Based on fuel consumption analyses, an LNG fuel tank size of approximately 6,000 cubic meters was found to be optimal, with bunkering in Australia for the round-trip. Several locations for the LNG fuel tank were considered, and finally the optimal solution was found – with the two LNG fuel tanks placed directly above the engine room and submerged a few meters below the main deck. This innovative design offers protection for the fuel tanks, enhances fire protection and does not reduce the cargo carrying capacity, even for volumetric cargoes such as coal.

“An important part of the JIP was conducting the financial feasibility study for the design,” said Mike Utsler, Woodside Chief Operations Officer. “We looked at a wide range of capital and operational costs, including LNG and low sulfur fuel oil price sensitivities, as well as conducting a high-level bunker supply chain assessment. Based on this we found that, under the most realistic scenario, the payback period for the design was under 10 years, and under the optimistic projection just 6.7 years.”

The design, presented at Nor-Shipping 2017, is ready to serve as the outline specification for newbuilding orders in 2017.

Vessel main particulars

Length overall: 300.0m

Breadth: 50.0m

Depth: 25.2m

Scantling draught: 18.5m

Deadweight at scantling draught: 210,000t

Cargo holds volume: 225,000m3

LNG tanks volume: 6,000m3

Main engine: WINGD 6X72 DF MAN B&W 6G70ME-C9.5-GI

Class notation: DNV GL, +A1 BULKCARRIER ESP BC-A GRAB[35] CSR, Holds 2, 4 ,6 and 8 may be empty, COAT-PSPC(B) GAS FUELLED