Managing Vessel Repairs with a "Digital Twin"

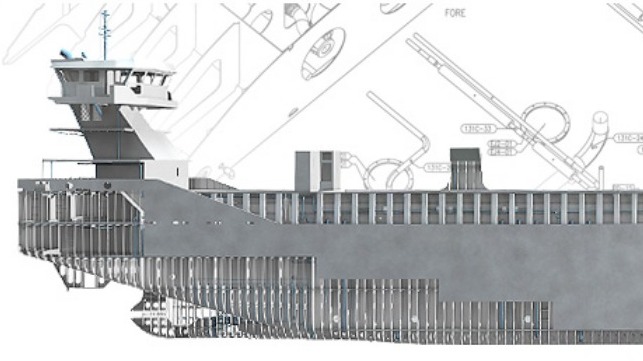

Vessel lifespans average between 30 and 50 years, thanks to ongoing maintenance, repair, and refit. Those consistent changes result in a ship that deviates significantly over its lifespan, making it difficult to maintain up-to-date design & build records of the ship that is currently being operated. Maintaining this “digital model” over a ship’s lifespan, with so many changes, requires working with information that comes from different sources, time periods, and technologies. Integrating these different sources of information can increase your understanding of your ship and dramatically reduce the overall cost of ownership.

As-built and as-maintained digital twins solve a large part of these problems but are still not being delivered to ship owners. With older vessels, information might only exist in legacy formats or on paper. This results in shipyards that don’t have the information they need to effectively plan for repair or refit, significantly increasing both time and monetary costs.

Today, one of the ways we see legacy data (2D PDFs) being managed is through a combination of additional new technologies that require the complex integration of platforms. For example, extracting toolpaths from 2D PDFs can put together a view of the general geometry and combining those views with laser scanned data directly from the ship allows you to explore those views in 3D space. The result is parts that can be created using this 2D PDF and laser scan hybrid as reference.

Increasingly, working with data and information to make it useful is absolutely necessary for shipyards to maintain competitive costs related to lifecycle management. But the reality is that over the lifespan of a ship, requirements, technologies, and information change. It’s unlikely that one system or subcontractor will have been responsible for every change made to the vessel, introducing opportunities for lost information or added costs associated with ensuring compatibility. Core to the solution is a single platform that can extract, curate, collate and share information across and between disparate sources.

Going forward, the solution that everyone is moving towards is an open platform of platforms ecosystem. With each platform in an enterprise architecture connected with another, you lower the risk of information being unusable when different software is used, or a hand-off occurs. The key is to avoid being locked in and optimize your ability to use the tools best suited for the job and use their outputs in every other part of a process or workflow. In reality, this can happen through available APIs, an open Architecture, leveraging commercial out-of-box tools (ex. SQL), or through a community of platform partners. This is the only way to ensure that your operation is flexible enough to adapt to future unknowns.

Nobody knows exactly the way their business, industry, or vision will evolve. Choosing a platform that you can build on, customize, connect with as needed, and update consistently allows you to make decisions with the confidence of future compatibility while still leveraging the ship information you already have.

The question of how to better integrate information throughout the lifecycle of a ship is increasingly brought up at the conferences we attend and by the ship owners we talk to around the world. That speaks to just how important achieving a solution is for our industry going forward.

For more information, visit SSI's Crow's Nest and Waveform blogs.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.