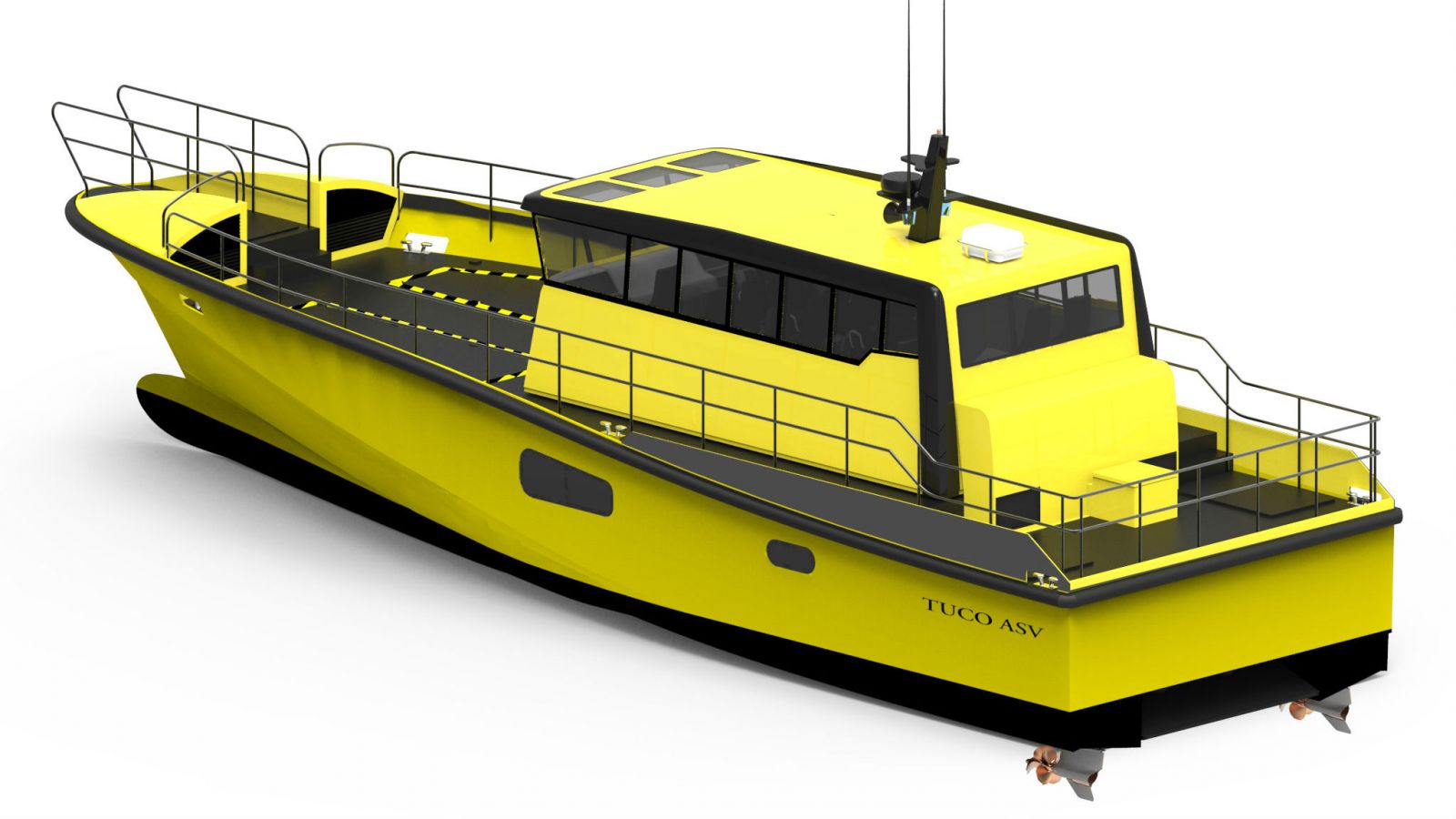

First Carbon Air Support OSV under Construction

The first carbon fiber, air supported OSV is under construction at Tuco Marine in Denmark.

The project is a combination of effort from Tuco Marine, Effect Ships International (ESI) and Diab. The team is combining ESI’s air supported vessel (ASV) technology with a light-weight carbon sandwich construction. Diab is responsible for the carbon sandwich engineering and Devinycell core materials, while Volvo Penta will be supplying engines and high efficiency IPS propulsion systems for the first of a range of vessels.

With support from The Market Development Fund (Denmark) and Norwegian Research Council, the first vessel, a 17.7m ASV monohull with a beam of 5.2m, is now under construction. It is expected to launch in autumn.

The ASV hull is a result of more than a decade of dedicated research and technological development. Through tank testing SSPA Sweden has documented a reduction in hull resistance of almost 40 percent. A 20m full scale ASV is showing similar numbers, says Ulf Tudem, General Manager of Effect Ships International. Compared with conventional monohulls, the ASV will have much less wetted surface areas and significantly reduced resistance. Resistance reduction of up to 40 percent has been documented.

The ASV hull is a result of more than a decade of dedicated research and technological development. Through tank testing SSPA Sweden has documented a reduction in hull resistance of almost 40 percent. A 20m full scale ASV is showing similar numbers, says Ulf Tudem, General Manager of Effect Ships International. Compared with conventional monohulls, the ASV will have much less wetted surface areas and significantly reduced resistance. Resistance reduction of up to 40 percent has been documented.

“ASV and carbon construction is a perfect match,” says Tudem. “New standards in efficiency and operational economy can be achieved. Reduced hull resistance and reduced outfitting weight gives improved speed and performance with less power. In many cases engine power (and weight) can be reduced by as much as 50 percent.”

Fuel Consumption

Fast work boats operated at high and for a considerable number of hours per year will see the largest fuel and operational cost savings, he says. Based upon documentation from a 20m full scale ASV and extensive tank testing the new carbon ASVs will offer very competitive fuel consumption per nautical mile, says Tudem.

Even a small 18m x 5.2m ASV deliver impressive numbers, he says. With 3,000 hours of high speed duty per year a fuel saving corresponding to 300,000-400,000 Euros ($336,000-$448,000) can be achieved compared with a conventional boat, depending on local fuel costs.

Hull Advantages

The ASV has a very low wake wash which is of great importance for many coastal operations with high traffic density, says Tudem.

While a planing fast monohull will face tough slamming impacts in waves at high speed, the air cushion chamber of an ASV will significantly dampen and reduce hull slamming and pitch motions, contributing to improved onboard comfort, safety and effective use of the vessel.

While a planing fast monohull will face tough slamming impacts in waves at high speed, the air cushion chamber of an ASV will significantly dampen and reduce hull slamming and pitch motions, contributing to improved onboard comfort, safety and effective use of the vessel.

The ASV mono can be described as a mono-hull with catamaran features. An ASV mono is normally beamier than a conventional mono-hulled vessel and will have almost vertical sides, resulting in a larger water footprint. Useful space inside an ASV mono is at least equal to that of a conventional mono vessel, says Tudem.

Air Support

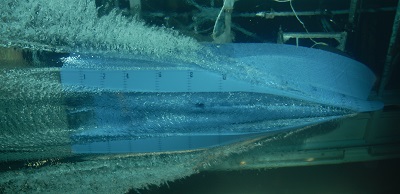

An air cushion chamber is covering the center part of the underwater hull, with planing buoyancy bodies (often referred to as propulsion gondolas) on either side. This configuration is very positive for reducing roll motion during low speed operation or at rest in waves.

A lift fan system is located in the far forward part of the hull, ducting air down and into the air cushion chamber, while a special air cushion enclosure arrangement is maintaining and controlling the ASV functions in the aft. With this patented set up, only 3-7 percent of the installed power is used to power the fan system to keep the vessel on the cushion.

For the Tuco ASVs the air support ratio relative to the operational displacement will be up to 85 percent. In a sea state more pressurized air will ventilate from the air cushion than in calm seas. The fan system will be specified to maintain a given cushion pressure with volume flow reserves also to handle more air ventilation in waves.

For the Tuco ASVs the air support ratio relative to the operational displacement will be up to 85 percent. In a sea state more pressurized air will ventilate from the air cushion than in calm seas. The fan system will be specified to maintain a given cushion pressure with volume flow reserves also to handle more air ventilation in waves.

In case of an unlikely situation that the fan system fails the vessel may be safely operated, as a semi-displacement vessel, naturally with higher resistance and reduced speed.

Applications

The first Tuco ASV has been designed to demonstrate and prove the concept for several applications including offshore windmill support, pilot shuttle, ambulance vessel, fast fire-fighting craft, fast navy applications and fast passenger transport.

Kevlar reinforcement can be added, and vessels with hull length between 15m and 45m are under development. Studio Sculli from Italy will assist in the design of the larger ASVs.

The 17.7m Tuco ASV has the following specifications:

Type of vessel: Air Supported Vessel Monohulled.

Applications: Offshore work boat, fast crew transfer, windmill support, patrol boat, pilot boat etc.

In survey to: DNV / Danish Maritime Authority

Owner/operator: Tuco and Effect Ships International

Builder: Tuco Marine, Denmark

Construction materials: Full carbon sandwich construction (hull and superstructure), vacuum infusion, Devinycell core material

Length overall: 17.7m

Beam: 5.2m

Base main propulsion engines: 2 x Volvo Penta D6, 320 kW each

Lift fan system: Centrifugal fan located in the bow

Fan powering: Single Volvo Penta D 3 engine (max capacity 130 kW)

Power transfer: Through Boch Rexroth hydraulic system

Propulsion: Pod Propulsion - Volvo Penta IPS 600 series 1

Alternative engines / propulsion: Volvo Penta IPS series 2 or 3

Maximum speed with base engines: 40 knots +

Service speed: 30 - 35 knots

Fuel capacity: 1,400 liters

Passenger seating: 12 PAX

Crew: 2

Estimated fuel consumption at 30 knots service speed (propulsion and fan system): 4.5 liter/NM.

Arrangement: The 17.7m ASV will have a full width large fore deck. Down below the vessel can be delivered with several arrangements including accommodation for crew. The first vessel will have a simplified arrangement.