Ballast Water Treatment Gets Easier with EcoOne™

By 2024, all seagoing vessels will have to comply with the requirements of the IMO Ballast Water Management Convention, and existing ships without a ballast water management systems (BWMS) must retrofit at their next renewal survey. These are busy times for treatment system suppliers, and to find out more, The Maritime Executive caught up with Ecochlor CEO Steve Candito for an update on the market and the latest in treatment technology.

TME: For background, why is ballast water treatment important?

SC: Ballast water management systems are essential for keeping marine species from moving between regions by traveling in a ship's ballast tanks. Let's say that a vessel discharges cargo at a port on the Amazon River, takes in ballast and travels to Florida. When the crew goes to discharge that ballast water, they're going to discharge organisms that are native to Brazil - not Florida. That leads to problems with invasive species, like the well-known zebra mussel and the Asian carp, which have infested the Great Lakes region.

TME: What sets Ecochlor apart?

SC: We are a bit different from the competition thanks to our patented treatment technology. Ecochlor is the only company on the market with U.S. Coast Guard- and IMO-approved chlorine dioxide (ClO2) technology, which is very effective at stopping the spread of invasive species. The other common alternatives for ballast water treatment are based on electrochlorination or UV treatment. Our product has been highly successful for our customers, particularly for large vessel shipowners who want a quality system that is not going to give them any trouble. These are companies like Anglo-Eastern, Angelicoussis Shipping Group, Alaska Tanker Company, Scorpio and - quite recently - Maersk Group.

Our ClO2 management system has significant benefits for the operator. It needs less power to run than any other option on the market; it is a cost-effective and scalable solution for the very largest vessels; it works equally well in freshwater or saltwater, warm water or cold water; it requires only one treatment on intake, with no second treatment or neutralization steps before discharge; it has no TRO sensors, which can interrupt ballasting operations; it is less corrosive to ballast tanks and piping than chlorine; and it is very user-friendly. The crew doesn't really have to think about its operation - they can essentially turn it on and it doses the ballast water at the right rate.

TME: How is your lineup evolving?

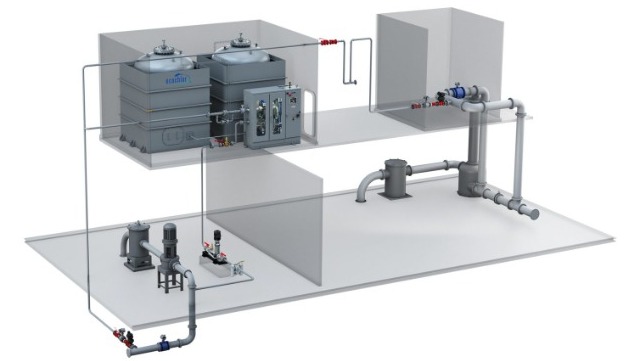

SC: We've just launched a new product that truly sets us apart from the rest of the market. Our new EcoOne™ system is a revolutionary, filterless BWMS that requires no pre-cleaning of the water at all.

The development of EcoOne™ started with customer feedback. We've heard from our clients that our ClO2 treatment is great, but that most of the BWMSs out there have mechanical filters, which can clog up in dirty water or cause other maintenance and operational issues.

We looked at this and realized that we could eliminate the filter from our system by slightly increasing the ClO2 dosing. UV treatment can't achieve this breakthrough because excess turbidity blocks UV light. Electrochlorination systems would also have a challenge in going filterless because the chlorine reacts with all organic matter in the water. Without filtration, the extra organic matter means that you would need significantly more chlorine to treat invasive organisms to the required standard - and more chlorine means more post-treatment neutralization as well as increased power and potential damage to the ballast tanks coatings.

On the other hand, ClO2 only reacts with living organisms. It does not interact with oil, debris or other organic matter in dirty water. That means that we don't need to use a much larger chemical dose if we remove the filter. On top of that, we never have to neutralize during deballasting.

We've completed the testing for IMO Ballast Water Management Code Type Approval and most of the U.S. Coast Guard testing for EcoOne™, but it will probably be Q3 and Q4 respectively, before the formal type approval. We're excited about it, and so is the industry, which has been eagerly waiting for a reliable BWMS without a filter.

It will be particularly beneficial for the owners of mid-sized to large vessels, who would otherwise have to buy and install a very large filtration system and would need to make time in drydock for the work. With EcoOne, that is no longer a requirement, and the savings for equipment, engineering and piping are quite significant – as much as 40 percent.

For vessels that ballast and deballast in certain freshwater environments, we offer a hybrid system that can automatically operate with or without a filter as needed. This is also a great option for vessels that already have an Ecochlor ballast water system with filters installed and would like to upgrade to an EcoOne™ Hybrid.

TME: How do you arrange periodic service for your clients?

SC: We recently hired a new VP of Global Services, Michael (Mick) Madely, who comes to Ecochlor with 25 years of senior management experience in commercial and technical roles. Over the past year he's been building out our service department throughout the USA, Europe and Asia, and we now have our own Regional Service Managers in major shipping ports like Singapore, Houston and Rotterdam. Mick has also been working on training up our network of Authorized Installation and Services providers at other locations With this upgraded network, we can dispatch service to a ship virtually anywhere in the world. When needed, we also have the capability to remotely assist a technician on board the ship via teleconference.

There are two things that are worth mentioning from a service perspective. First, our system doesn't need a lot of maintenance to begin with, because it's mostly pumps and valves and other basic components that most vessels' crews will be familiar with. The most complex element of our equipment is the mixing chamber for our two chemicals, and that component has no moving parts. We keep statistics of each ballast operation performed by the ship’s crew, and our equipment's uptime is well into the range of 98 percent for continuous operation.

Second, we size the storage tanks for the treatment chemicals to give the ship about six months' worth of supply, based on the owner's operating profile. We visit each of our clients' vessels about twice a year to replenish the supply of chemicals on board. Since that's part of our service, the owner doesn't have to go out and source the chemicals or handle any of the logistics of getting the chemicals on board the vessel. With feedback from the crew using a report automatically generated by the system, we help monitor the tank levels remotely so that we know when it's time to schedule a refill. When our technicians come onboard to provide that regular service, they also take the opportunity to have a look over the system to see if anything is out of the ordinary, and this can help catch potential problems early, even before they start.

TME: Which vessels stand to benefit most from your technology?

SC: Mid-sized to the largest ships in the world are particularly well placed to benefit from Ecochlor's range of treatment systems. We have the largest flow rate capacity in the industry, and our systems are modular and scalable. These vessels are also where EcoOne™ will be most cost-effective to operate, and very competitively priced in comparison to other systems We're finding that many of our customers see enough value in our product’s reliability and strong service support that they're choosing Ecochlor for the ‘peace of mind’ in knowing the system will operate effectively through future regulatory updates and for the life of the vessel.

To learn more about EcoOne™, visit https://ecochlor.com/ecoone/.

This message is sponsored by Ecochlor.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.