All Marine Spares Named Authorized Dealer for DHP

DHP was the first and the best Plate Heat Exchanger company in Korea since its establishment in 1978. But now, it rises as world best plate heat exchanger company in the world.

Korea was an excellent ship building country through out the history and now it is world famous and moreover it will still be the best because DHP is standing in the heart of ship building.We can cool down lubrication oil temperature and fresh water temperature with sea water or fresh water. And we return the heat for ship again to get fresh water and heating.

We do the same service for power plant, chemical plant, fresh water generator plant and industrial area. We do not consume heat at all in the plant instead we change the heat direction for users wish. Heat exchanging without any energy consumption is our mission. If there is heat exchange problem that is charged with DHP. We can service the best solution. See our Products below.

Plate heat exchangers

Principle

Plate heat exchangers have more than 100 years history and its structure is composed of a fixed frame, a movable frame and corrugated plates which are in between the two frames.

Hot liquid and cold liquid go through between the corrugated plates in turn.

To prevent leaking, gaskets are mounted around the plates and tightening bolts are used to put the plates together.

There is heat transfer between the two liquids through the plates.

This is the main principle of a plate heat exchanger.

The arrangement of two liquids is that the cold liquid goes upward and hot liquid goes downwards in order to increase heat transfer efficiency.

There is an advantage to use plate type heat exchangers over Shell & Tube type heat exchangers, that is to say, the corrugations in the plates reduces the liquid turbulence to a low Reynolds number and the liquids flow is counter current so that the heat transfer efficiency is always 3 ~ 5 times higher than Shell & Tube type heat exchangers.

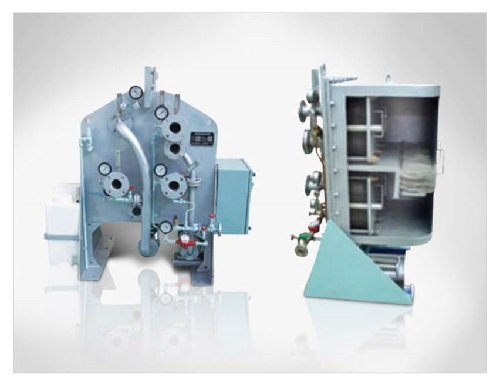

Disk & Shell heat exchangers

Overview

DHP's new development 'Disk & Shell Heat Exchanger' is a heat exchanger which is composed of the good points of shell & tube heat exchanger and plate heat exchanger.

This heat exchanger is welded plate pack in high pressure vessel.

The maximum pressure is up to 100bar and the temperature is up to 400°C.

The main application is condenser, evaporater and the units require high pressure and high temperature but small size.

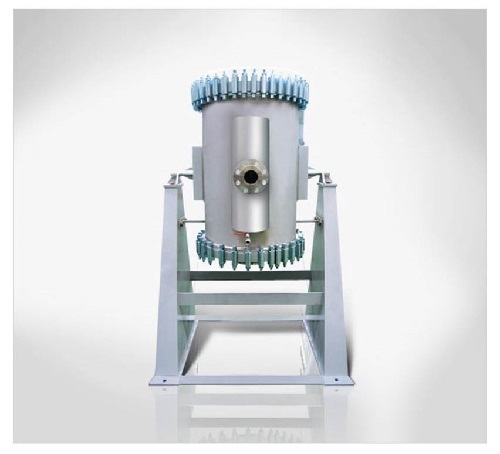

Spiral heat exchangers

Overview

Type I (BSFX) : Both Sides Spiral Flow Heat Exchanger

It enables both side fluids to form perfect counter flow, so the heat transmission is possible at minor difference of temperature and even when the contaminated substance in the fluid stays at wall surface or bottom due to the decrease in flux or stand by during the operation and once the flux is recovered it works as self-cleaning for the contamination due to the speed increase by the sectional decrease in flux passage of the part attached with the contaminated substance.

Type II (CSFX) : Cross Spiral Flow Heat Exchanger

It has a structure that the heat transmission between fluids occurs vertically and it is used for processing such mixtures or steam, gas or evaporation in large capacity.

The fluid passing vertically will go through heat exchanger at high speed with almost no pressure loss as a media for mainly steam or gas but sometimes it can be used for heat exchange of Liquid:Liquid which has much difference in the flux.

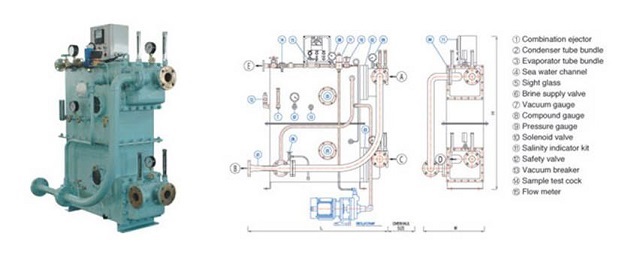

Fresh Water Generator

Overview

To achieve fresh water for drinking and washing, vacuum distillation system is normally use in the isolated place such as on ships or on islands.

The DHP vacuum evaporating distiller utilizes heat from diesel engine coolant and LP steam by special steam jet heater.

The DHP vacuum evaporating distiller is base on the DHP's titanium plate heat exchager, one for evaporating of the heated brine and the other for condensing of the water vapor.

The vacuum chamber is kept by the seawater driven from condenser combination ejector.

Heated seawater is used as feed water (brine) for the evaporating and evaporating temperature is controlled by vacuum pressure.

Evaporating pure water vapor passes through deflector, demister and moving water droplets and then enters the condenser.

The pure water vapor condensed by cold seawater.

The distillated pure water pumped out by fresh water pump and checked salinity.

If the salinity exceeds the specified level, solenoid valve opens in the discharge line of the fresh water pump, this is automatic operation.

The salinity exceeds distilling water is returned to evaporating chamber.

5TPD Type Single-stage Fresh Water Generator

30TPD Type Single-stage Fresh Water Generator

30TPD Type Single-stage Fresh Water Generator

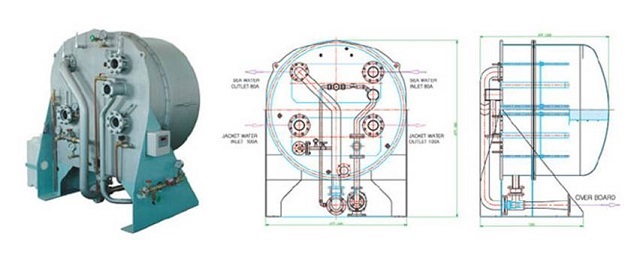

MVR(Mechanical Vapor Recompression Distiller)

The products and services herein described in this press release are not endorsed by The Maritime Executive.