SMM: Suppliers Compete to Create Ships' E-Networks

At this year's SMM in Hamburg, manufacturers of all types of ship equipment – from ECDIS to control systems to propulsion systems – presented visions of an interconnected, data-driven future for shipboard operations.

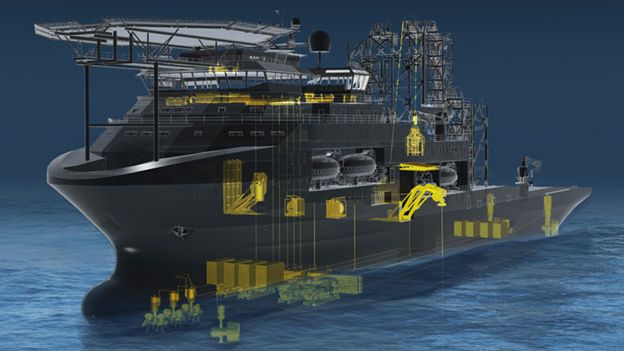

The trend is not restricted to the makers of marine electronics: rather than highlight its decades of experience in the design of diesel engines and propulsion systems, Wärtsilä emphasized its "capabilities in the field of digitalisation and its thought leadership on the future of global shipping" with a conceptual presentation of its "vision of future maritime concepts." This focus reflects the firm's drive towards what it calls "integrated solutions" – a network of shipboard systems all supplied by the same manufacturer and all interconnected. "It is no longer always enough to provide individual products or systems, since the essential global need for optimal efficiency and minimal risks demand that all these individual parts function together, as a single integrated, harmonious entity," the firm says.

In a similar vein, azipod maker and automation provider ABB announced an expansion of its OCTOPUS ship management software, which now combines weather, cargo, shipboard equipment, trim, propulsion and other data within one digital hub – and allows shoreside operations to see the same picture. The system is already deployed on over 400 ships. “For the first time we are bringing together two important features in the marine industry, energy efficiency optimization and safe voyage execution, into the same software and analytics platform,” said Mikko Lepistö, Senior Vice President of Vessel Information and Control.

ABB manufactures shipboard equipment which can communicate with OCTOPUS, but the software is intended for the general marketplace and can interpret data from many other suppliers’ devices, the firm says.

Bridge electronics makers Kongsberg and Transas also presented new ventures in connected shipboard systems: Transas is continuing its work to bring full vessel navigation and operating data to shore, connecting the ship directly to vessel traffic system (VTS) centers and to ship operations managers. Kongsberg, in conjunction with Schneider Electric, announced plans to change the market for multiple types of shipboard equipment, from electrical panels to walk-to-work gangways – with new products similar to existing offerings from other manufacturers, but networked and automated, potentially creating new efficiencies. Kongsberg is building new partnerships with firms like Schneider and Siemens as it seeks to expand in what it describes as "'Integrated' vessel concept strategies.”

Why the widespread emphasis on creating an ecosystem of integrated, networked systems? First and foremost, the collection of all shipboard data in one place promises to improve efficiency of operations, making a solid value proposition for shipowners. One industry observer also suggests that "ownership" of a ship's electronics network may help a supplier to bundle a larger set of equipment for a high-end newbuild – selling not just the electrical distribution system, for example, but also the variable frequency drive controls, bow thrusters, DP system and more, all built by or purchased through one supplier, all tied together through the supplier's shipboard digital network system.

There is still plenty of room for automation and monitoring products designed to improve operations without a shipwide network, though: in addition to its future concepts presentation, Wärtsilä also introduced a new stand-alone tailshaft monitoring system at SMM, which can eliminate the need to pull a seawater-lubricated shaft every five years to satisfy class requirements; most of the installations of this system to date are set up to function independently, says spokesman Matthew Bignell. Likewise, Wilhelmsen Ships Service's newly introduced boiler water dosing system, while highly automated and capable of communicating its operating status, is designed to function on its own – at least for now.